Comparison of Hydraulic and Traction Elevators

Choosing the right type of elevator for residential buildings directly affects cost, speed, comfort, and maintenance. The two most common options are traction and hydraulic elevators: the first operates with motors and cables, while the second works with a piston (jack) and a power unit. In this guide, we review the key differences in terms of suitable height, speed, energy consumption, installation and service costs, space requirements, and safety—helping you decide which option is more practical and cost-effective for your project.

In this article, you will learn:

What is a traction elevator, and what are its pros and cons?

What is a hydraulic elevator, and what are its pros and cons?

What is a Traction Elevator?

A traction elevator is the most common type used in high-rise and high-traffic buildings. It operates with steel cables and either a geared or gearless motor. In this system, the cabin and the counterweight are connected to opposite ends of the cable, and the motor drives the movement of the cables.

Advantages of Traction Elevators

- High speed → Up to 2.5 meters per second (suitable for buildings with more than 6 floors or residential towers).

Lower energy consumption → Thanks to the counterweight, the motor bears less load.

Smooth and vibration-free movement → Especially in gearless models.

Suitable for tall buildings → Practically no limit on the number of floors.

Disadvantages of Traction Elevators

Higher initial cost → Both in equipment purchase and installation.

Space requirements → Needs a machine room or special shaft, although machine-room-less (MRL) models are also available.

Higher maintenance costs → More components, such as cables, motor, and brakes, require regular inspection.

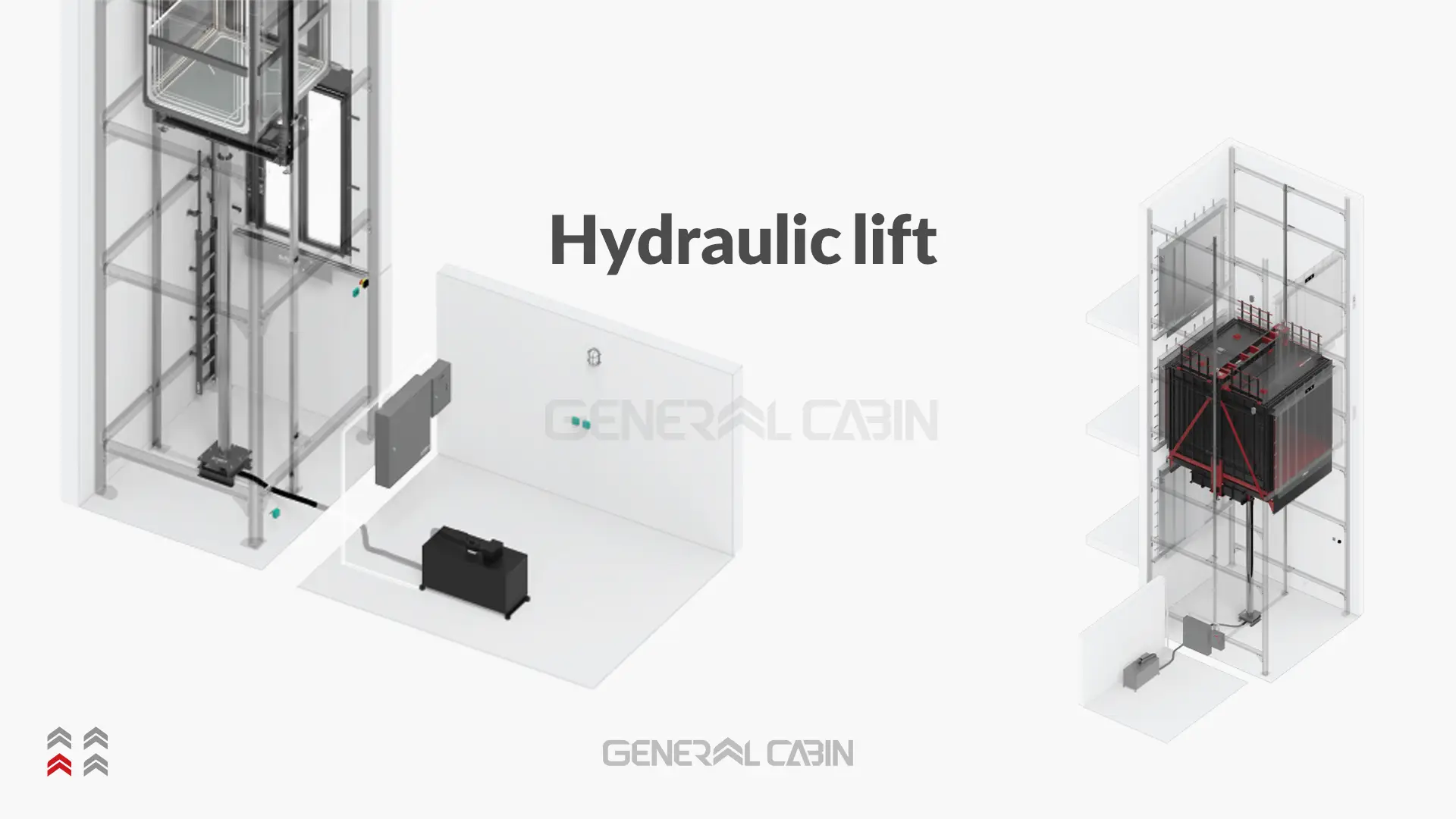

What is a Hydraulic Elevator?

Hydraulic elevators are mostly used in low-rise residential buildings. Their movement is powered by a hydraulic jack and an oil pump. In this system, the cabin is lifted by the pressure of oil inside a cylinder, and when descending, it moves under its own weight as the oil flows back.

Advantages of Hydraulic Elevators

High safety → Even if a cable breaks or a malfunction occurs, the cabin will not fall suddenly.

No large machine room required → Equipment is installed at the lowest level or next to the shaft.

Flexible installation → Can be used in buildings without a standard shaft, ideal for renovation projects.

Lower initial cost → Generally cheaper than traction elevators.

Smooth and quiet ride → Especially noticeable during start and stop.

Disadvantages of Hydraulic Elevators

Lower speed → Typically between 0.6 and 1 meter per second (best for 2–6 story buildings).

Higher energy consumption when going up → Because the motor directly lifts the load.

Maintenance of oil and hydraulic components required → Includes oil replacement and leakage checks.

Height limitations → Not recommended for high-rise buildings or towers.

Probability of Stopping at Floors

| Feature | Traction Elevator | Hydraulic Elevator |

|---|---|---|

| Suitable Building Height | No height limitation – ideal for high-rise buildings | Best for low-rise (2–6 floors) |

| Speed | Up to 2.5 m/s (fast) | 0.6 – 1 m/s (slower) |

| Energy Consumption | Lower, thanks to counterweight | Higher when going up (motor lifts directly) |

| Initial Cost | Higher (equipment & installation) | Lower compared to traction |

| Maintenance | Higher – cables, motor & brakes need frequent checks | Hydraulic oil & pump require regular service |

| Space Requirement | Needs a machine room (MR or MRL options) | No large machine room, equipment fits at shaft bottom |

| Ride Comfort | Smooth, especially gearless models | Soft start and stop, quiet movement |

| Safety | High – but relies on cables and brakes | Very high – cabin won’t free-fall even if failure occurs |

Conclusion

The choice between traction and hydraulic elevators directly depends on the building height, budget, and residents’ needs.

If your building has more than 6 floors or experiences heavy traffic → a traction elevator is the best option, offering higher speed and efficiency.

If your building is low-rise (2 to 6 floors) and you’re looking for a more economical yet safe solution → a hydraulic elevator will be more suitable.

Ultimately, consulting with a professional elevator company ensures that the decision is tailored to the technical requirements of your building.