Elevator Motor

Typically, the most important part of an electrical device is its motor, which is known as the beating heart of mechanical devices. Elevators are no exception to this rule, and the elevator motor is considered one of the essential components of this device. This motor provides the necessary force for the movement and displacement of the elevator cabin. High-quality and top-grade elevator motors provide quality performance and greater stability, demonstrating higher resistance to potential hazards.

As the heart of the elevator, the elevator motor generates the force required for the movement and transfer of the cabin. Without this motor, the elevator cannot function properly and will be unable to move. In addition to carrying the weight of the cabin and incoming loads, this motor is responsible for generating the necessary force for elevator movement.

Types of Elevator Motors

Elevator motors are produced in various types based on technical features, building requirements, and usage environment.

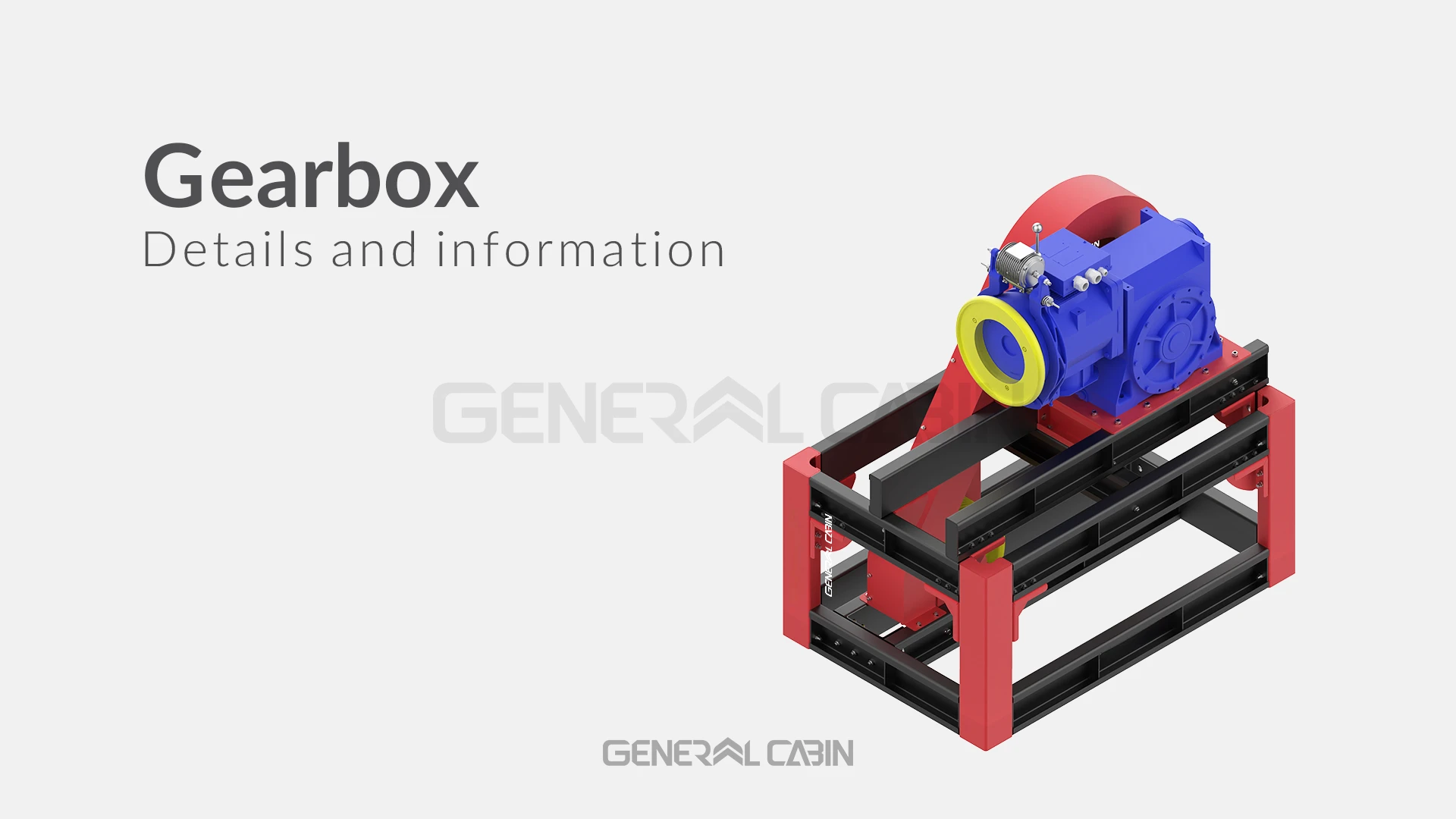

1. Geared Motors:

These motors have a gearbox system that increases the power and torque of the motor.

Geared motors are typically used in buildings with medium height and medium to heavy loads.

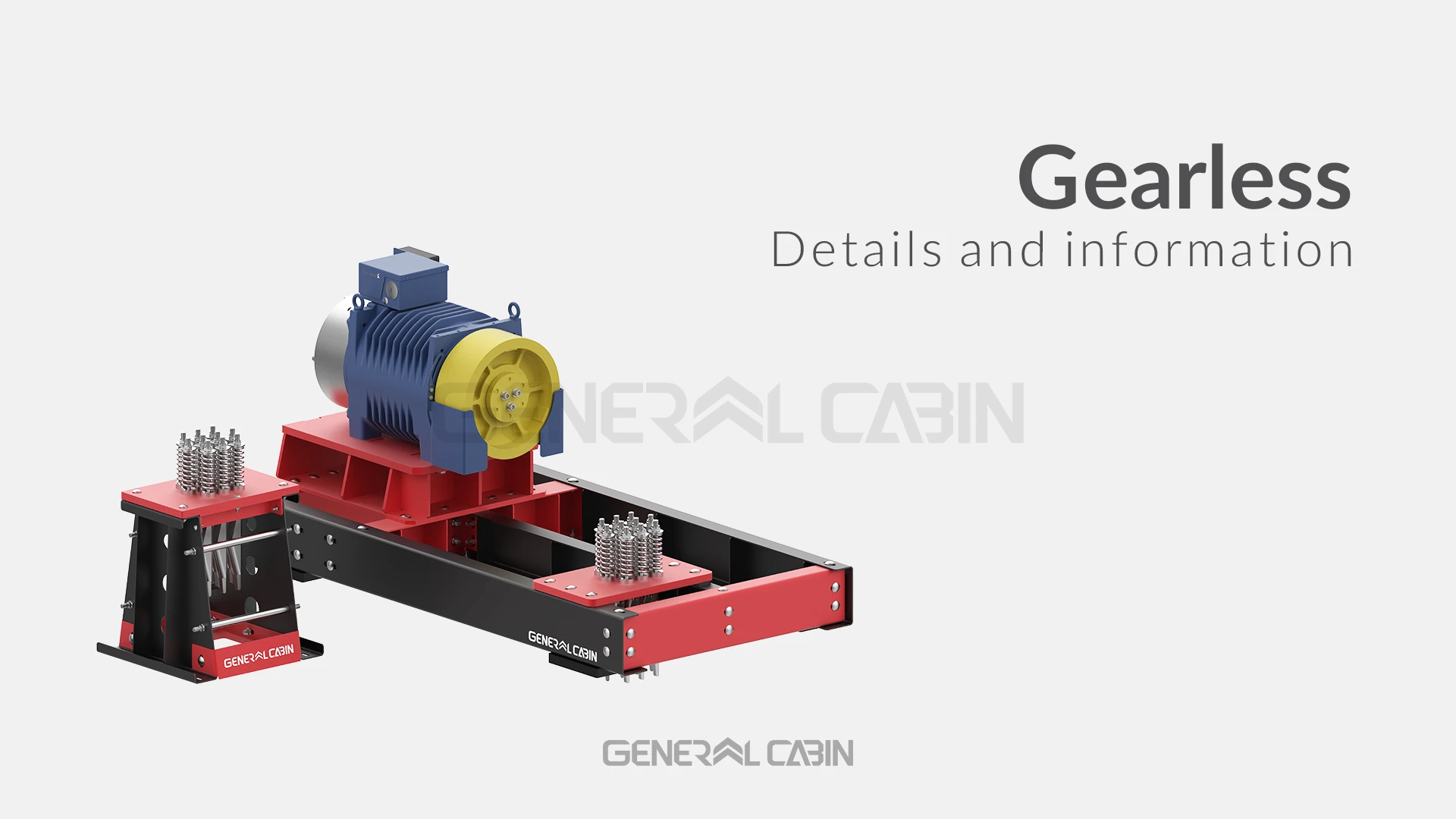

2. Gearless Motors:

These motors operate without a gearbox system, reducing noise and increasing efficiency.

Gearless motors are commonly used in tall buildings with heavy loads as they offer better technical and operational efficiency.

3. Synchronous Motors:

These motors operate based on electromagnetic principles and synchronize with AC electric current.

Synchronous motors are used for smooth and stable elevator movement as well as applications requiring precise speed control.

4. Asynchronous Motors:

Often referred to as dual-speed motors, these motors are typically used in elevators with smaller capacities.

Asynchronous motors use AC to generate movement in the elevator and are also considered an economical option.

Each of these motor types has its features and specific applications, and selecting the best motor type based on the specific requirements of the building and expectations for elevator performance is crucial.

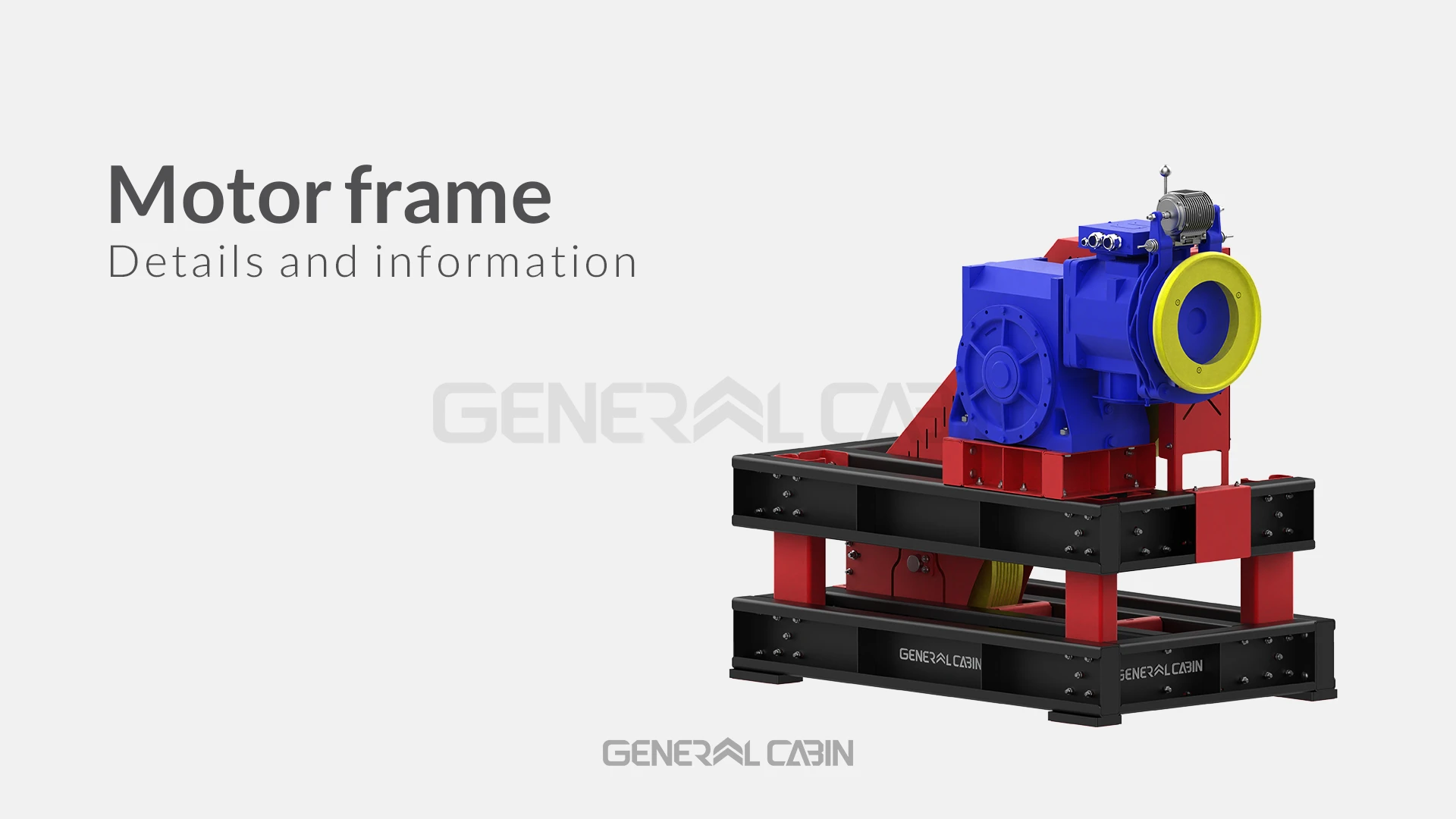

Motor Frame

The motor frame of an elevator is a metallic structure upon which the elevator motor and sheave are mounted. This frame, acting as a fundamental element in the elevator system, provides a suitable location for installing and positioning the motor. Additionally, another component called the sheave is placed on this frame.

The importance of the motor frame lies in bearing the weight of the elevator cabin, the traction rope, and other mechanical components. This structure prevents unnecessary horizontal and vertical movements in the cabin and ensures stability, strength, and vertical distance between components. Among these distances is the distance between the motor sheave and the traction sheave from the frame, which plays a crucial role in the proper functioning of the elevator.

General Cabin Elevator Motor Frame Features:

- Customization according to elevator speed and capacity

- Calculation of alpha proportional to elevator speed and capacity

- Installation capability for governor sheave and traction sheave

- Precise adjustment capability of traction sheaves

- Installation of shock-absorbing rubber

- Consideration of governor placement (governor base) if necessary

- Use of electrostatic paint

- Screw and nut-type connections