The materials used are as follows

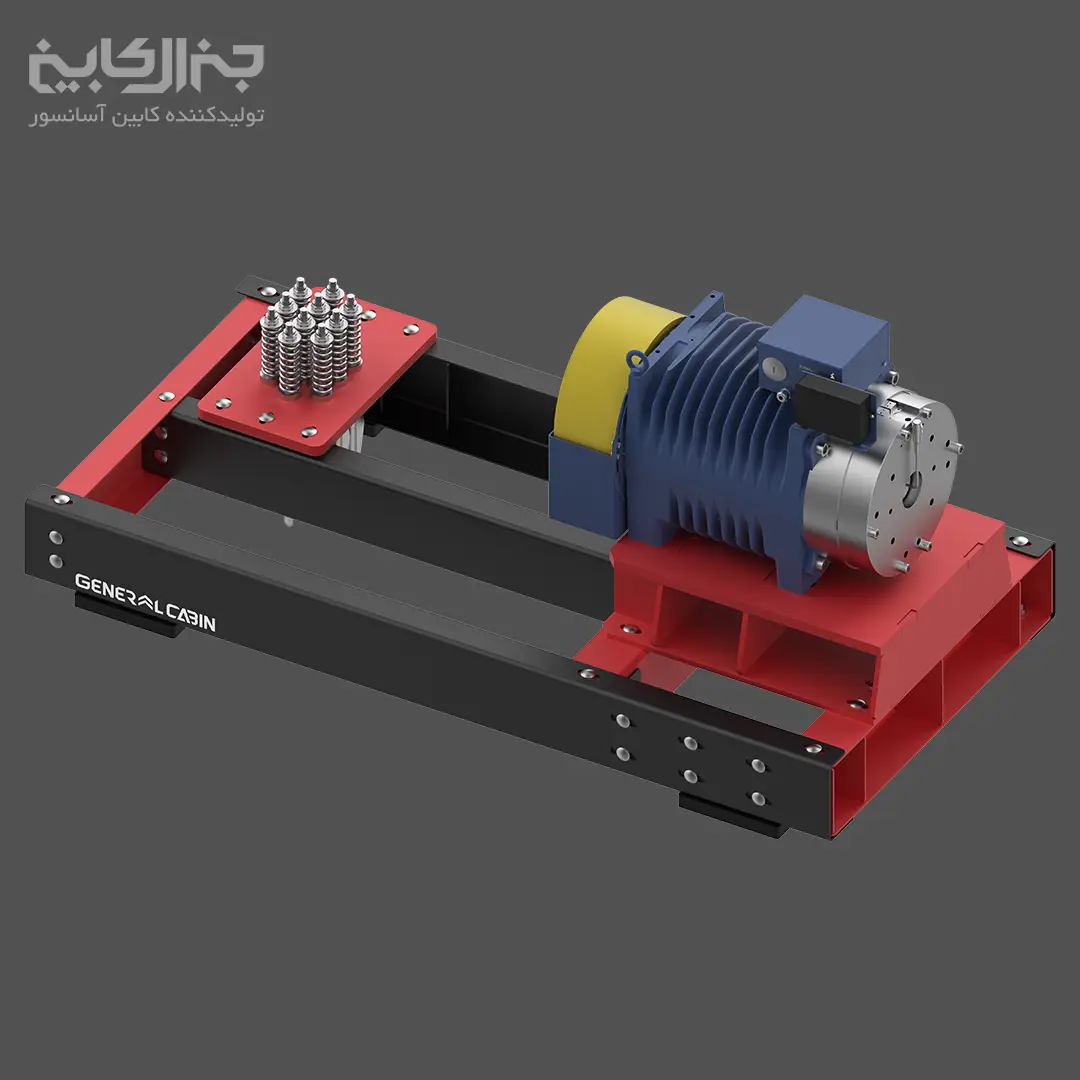

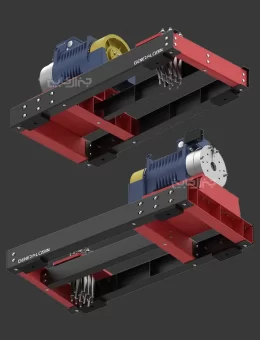

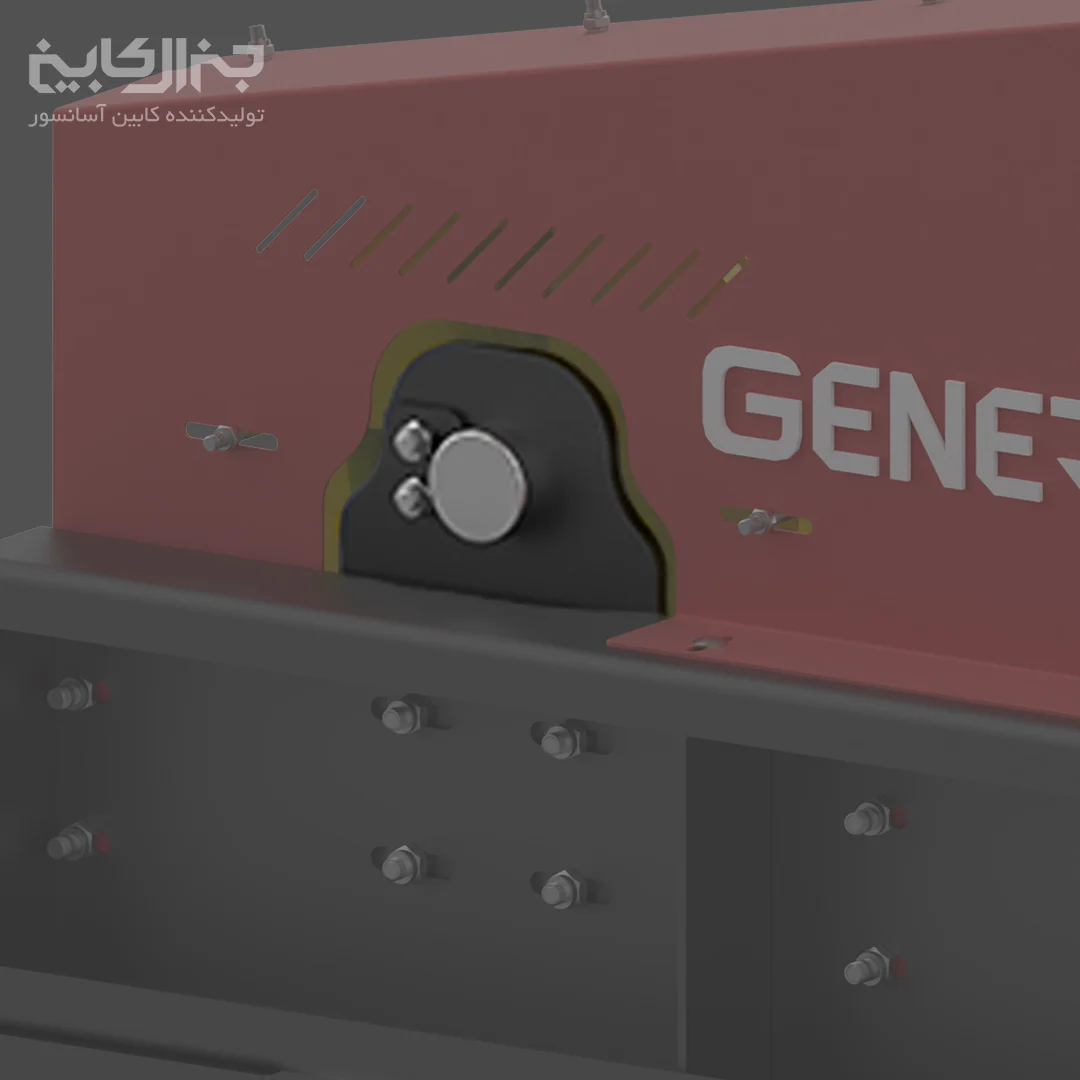

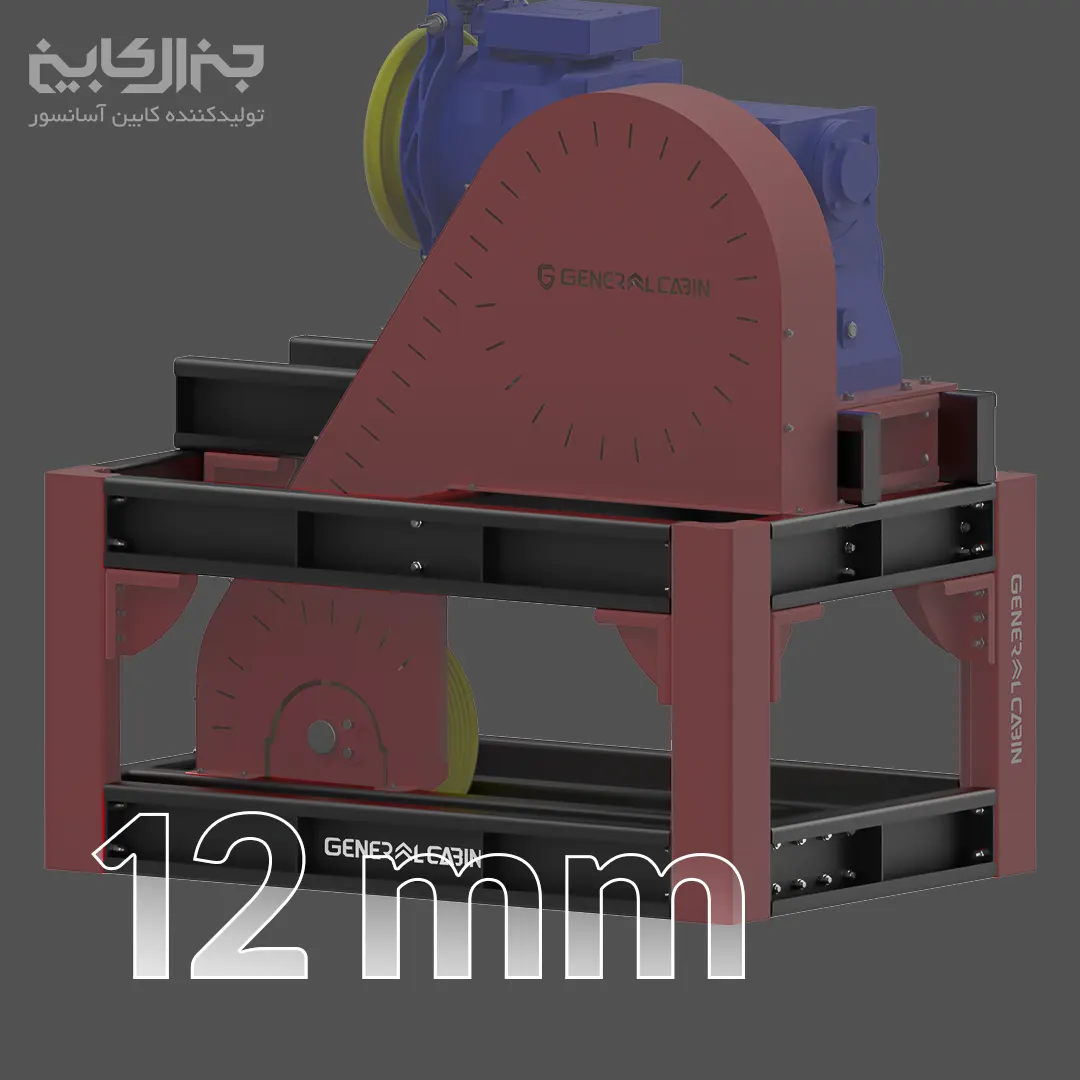

Elevator motor base

MotorFrame

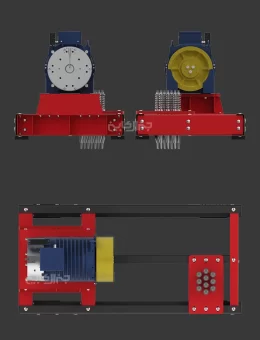

Blueprint

Engineered

Paint

Electrostatic

Production

Industrial

Structure

Bolted joint

Sheet Type

Steel

Standard

EN-81

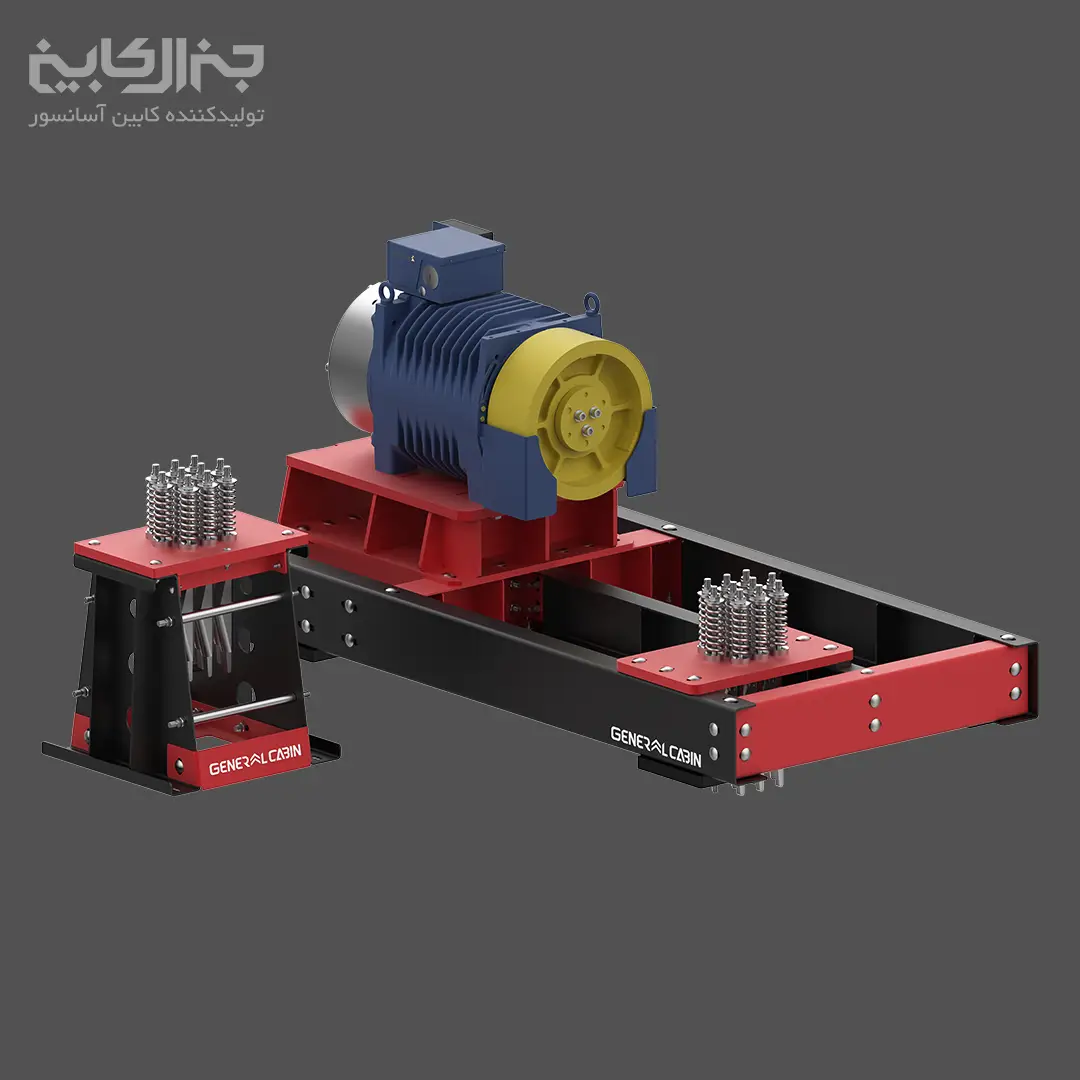

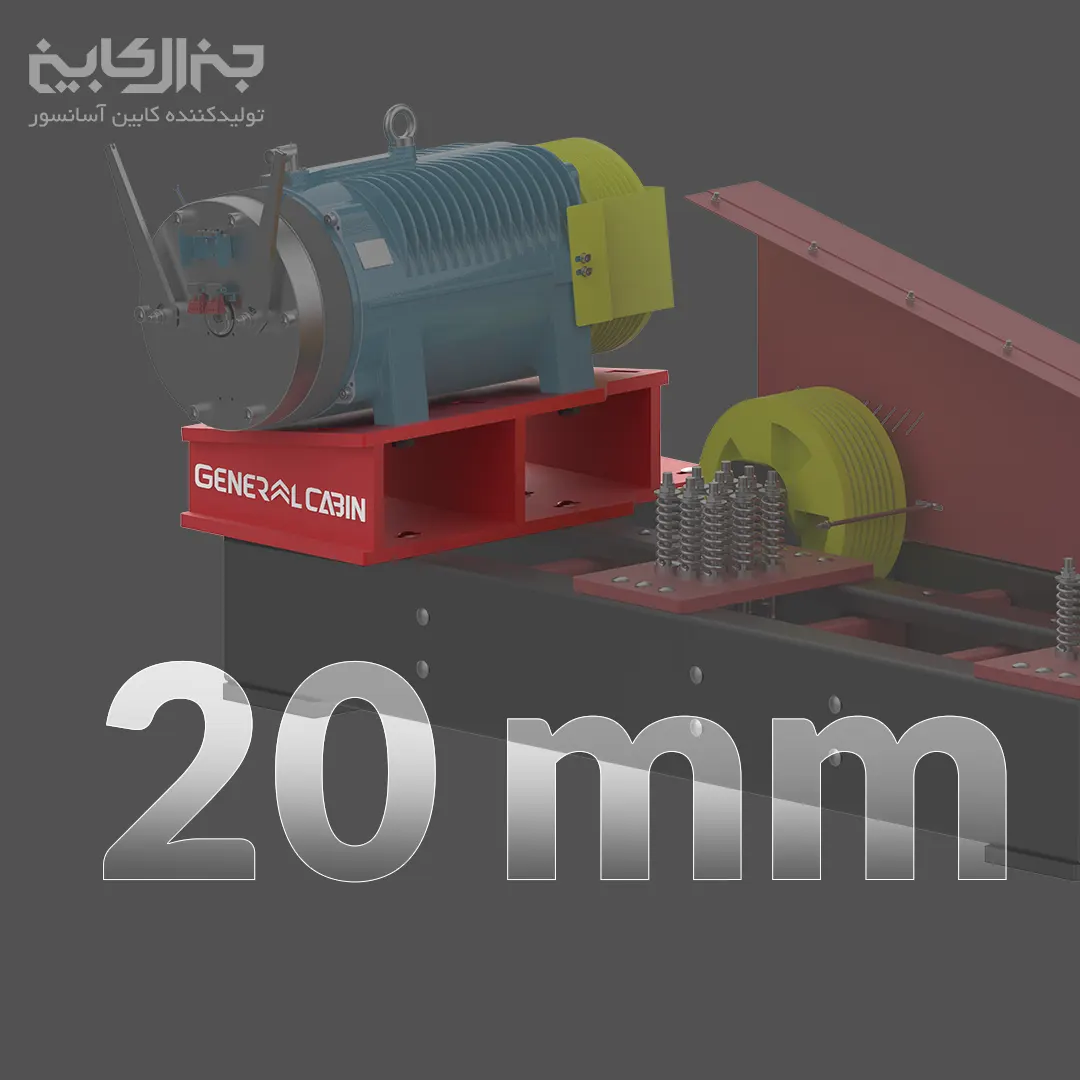

Alternative Elevator Motor Mounts

Elevator motor base

Motor Frame

The materials used are as follows

Engineered

Sheet Type

Steel

EN-81

Bolted joint

Electrostatic

Industrial

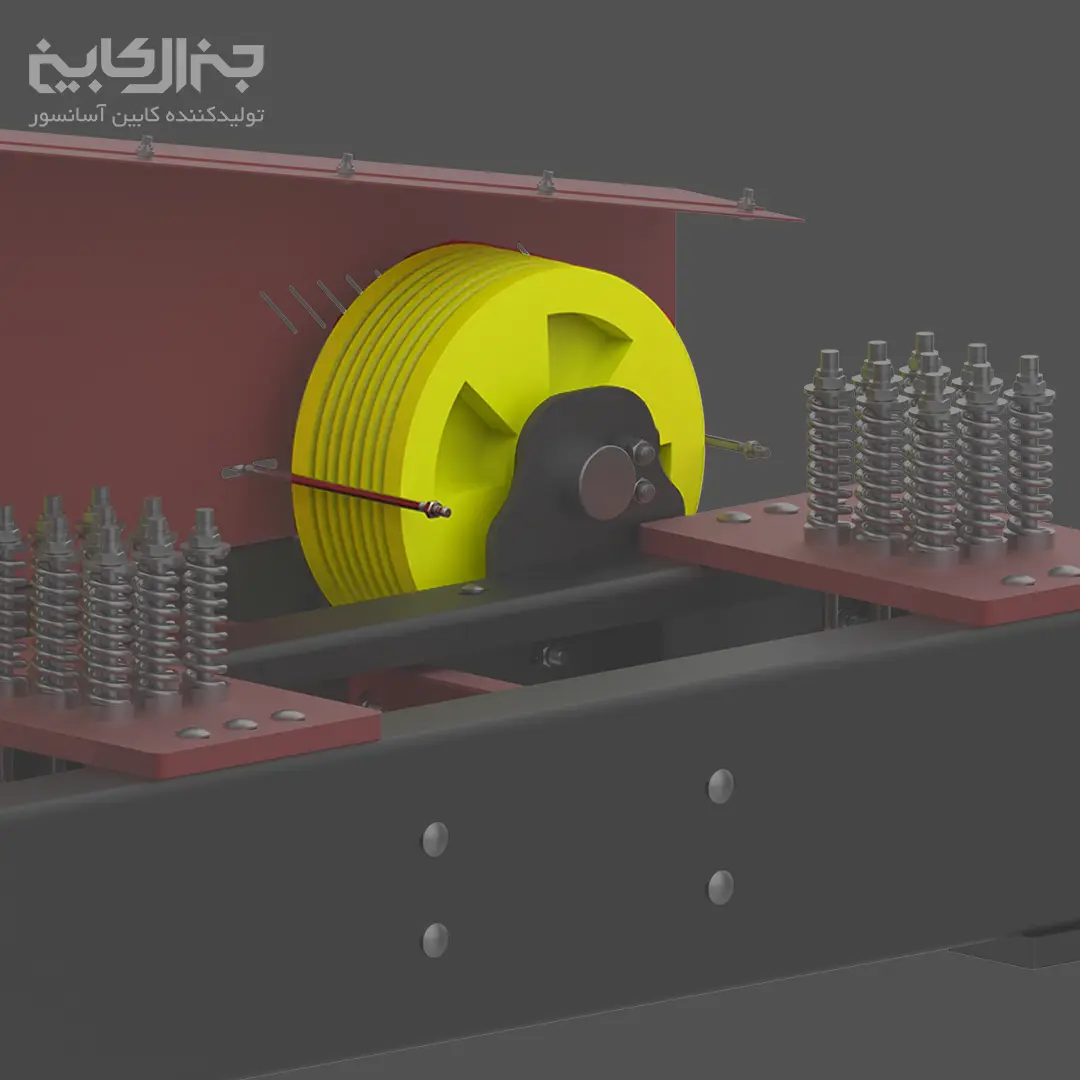

Types of engine bases

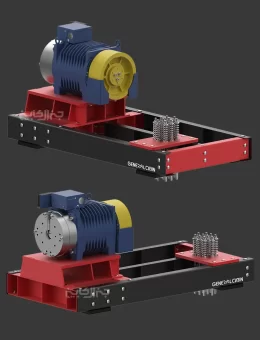

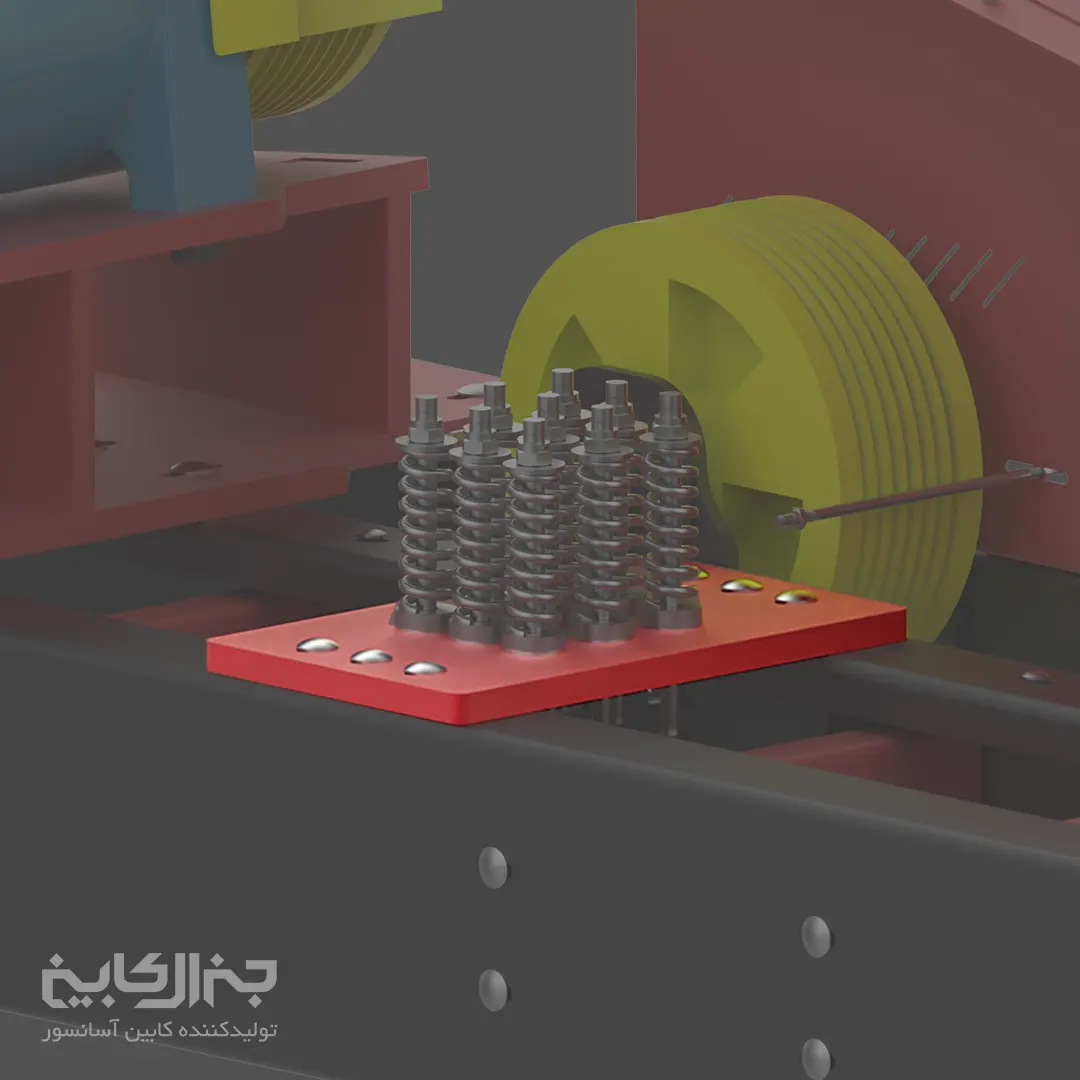

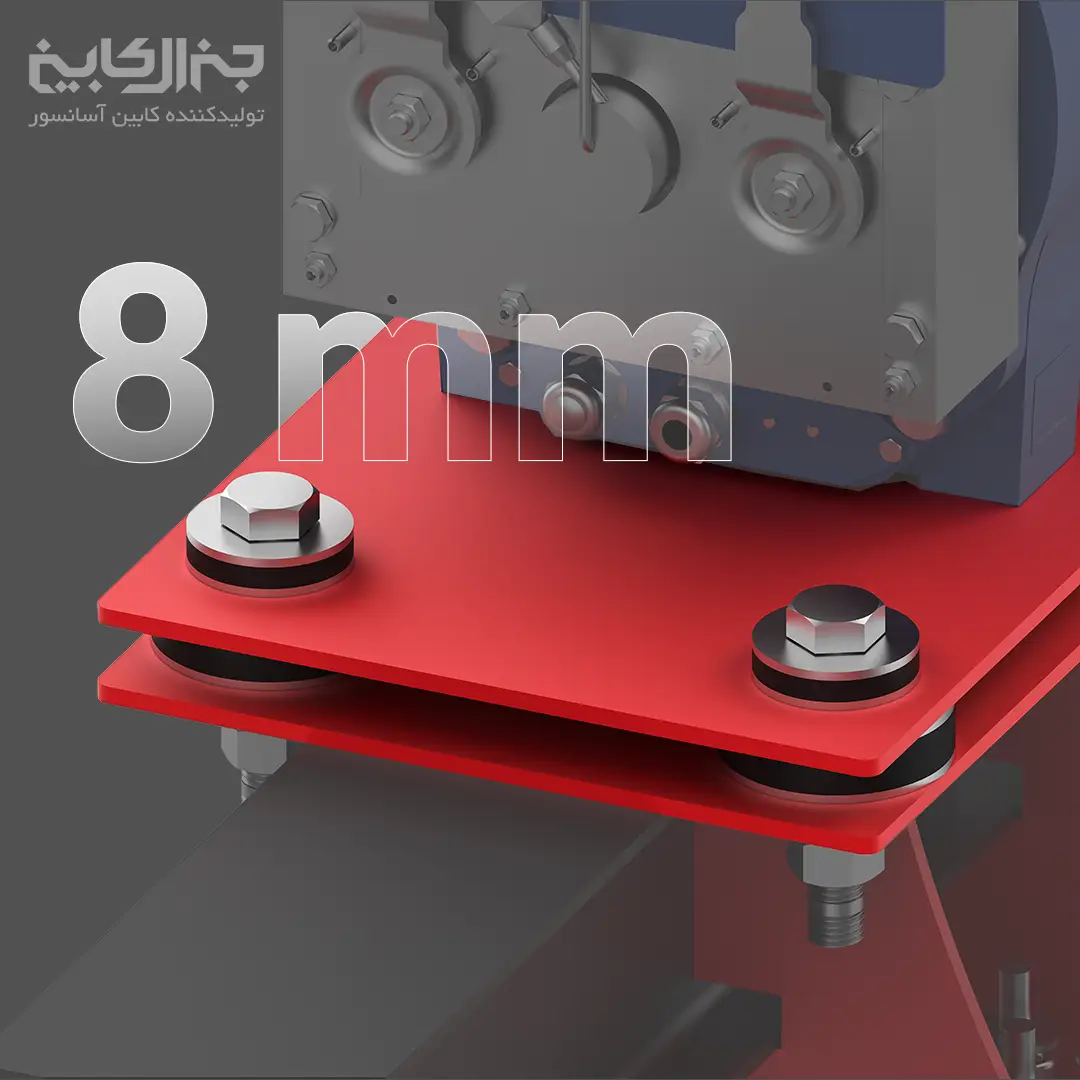

Motor Mount Accessories

Motor Mount Accessories

Accessories provided with the purchase of an elevator motor mount

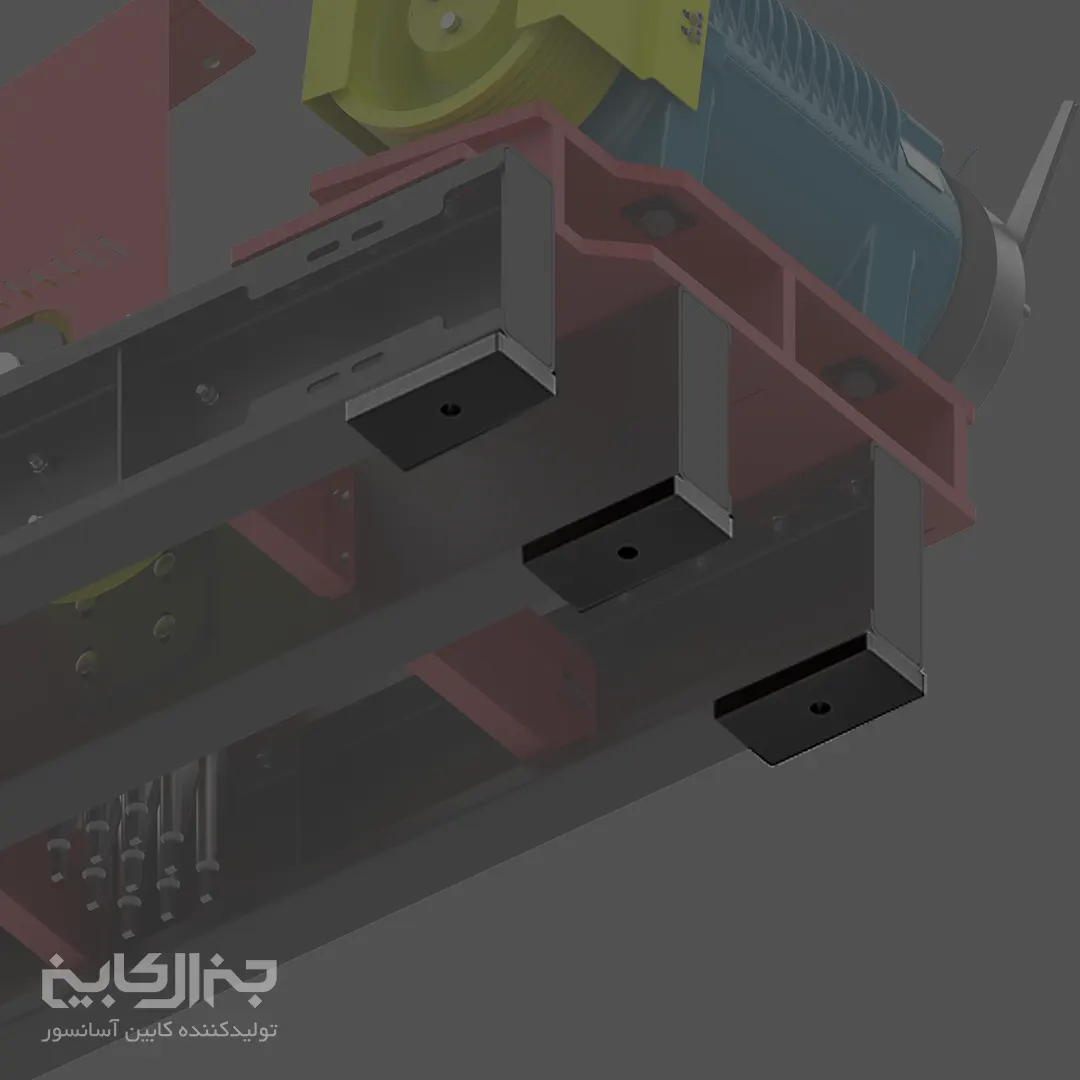

The General Cabin’s weight frame includes sliding shoes, auxiliary shoes, flange covers, the ability to weigh up to the highest height, buffer plates, and the ability to increase the length of the weight frame in a modular form.

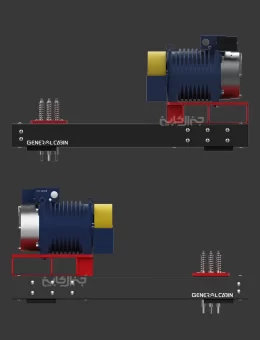

Product Features

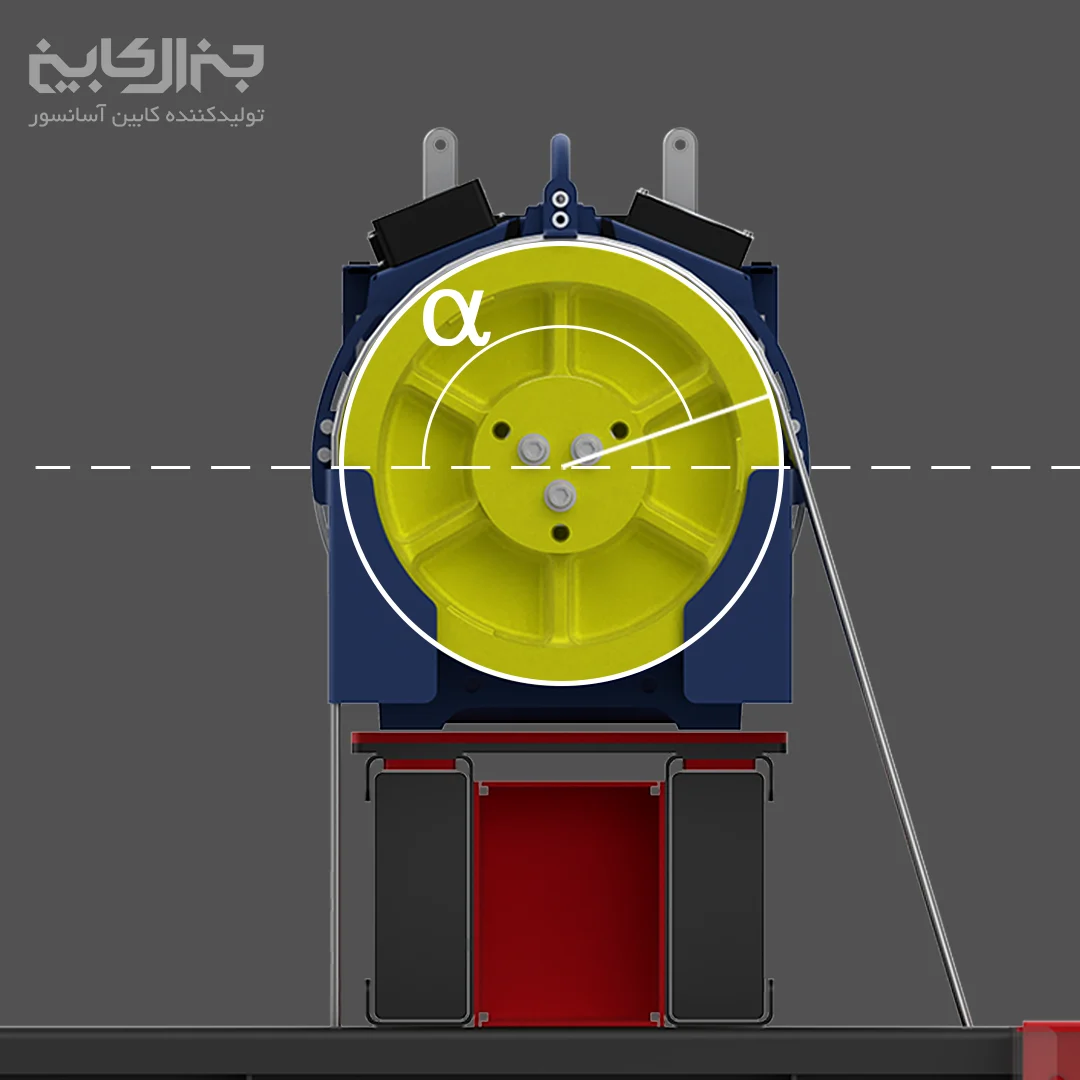

Some important features of General motors engines include

Different parts of the weight frame, depending on the type of elevator and the engineering design, are made from galvanized sheet metal with various thicknesses ranging from 4 to 8 millimeters. The sheet metal is coated with high-quality, electrostatically applied paint with precise and high-quality coverage.

Thickness of sheets

The thickness of the steel sheets for the weight frame will vary depending on the capacity and usage of the elevator.

Technical specifications

Free consultation and design of your elevator cabin

We will design your elevator cabin completely free of charge.

Other Products