What is a Guide shoe?

One of the main parts of the elevator cabin is the shoe, which has a good effect on the smooth movement of the elevator cabin and the counterweight of the elevator.

The shoes are installed at the bottom and top of the counterweight and the cabin, and their main task is to guide the counterweight and the cabin along the elevator guide rail. Shoes are produced in different types and materials, prices, and qualities.

What is the use of elevator shoes?

Contrary to its small appearance, this elevator component has many applications. Guide shoes are used in all elevators, including hydraulic, traction, and magnetic ones. As mentioned, the main role of guide shoes is to assist in the smooth movement and reduce the slippage of the elevator cabin and the counterweight along the elevator guide rails. All this contributes to the improved movement of the elevator.

Elevator guide shoe Types

In general, 3 types of guide shoes are used in elevators:

Roller guide shoes: These guide shoes are placed as three rollers on the machined faces of the rail. The collection of these three rollers and their base comprises the roller guide shoe, which is not sliding. Each roller in these guide shoes has a spring that prevents the transmission of a significant amount of shocks from irregularities by absorbing them, to the cabin. The quality of the bearing material and the polyurethane used impacts the effectiveness of the roller guide shoes.

Sliding guide shoes: The most common type of shoe blocks are the sliding guide shoes, which consist of different pads including rubber, polyurethane, and Teflon. Because sliding guide shoes are in full contact with the rail and have no slack, they transfer almost all imperfections and vibrations from the rail connection points to the elevator cabin. However, some shoe blocks, like Hitachi guide shoes, absorb many of these shocks from irregularities. The maximum usable speed for these shoe blocks is 2.5 meters per second.

Fixed Guide Shoes

Features of General Cabin Guide Shoes

Vibrations and shakes always occur when the elevator cabin passes over the rail joints. The guide shoe neutralizes these vibrations and ensures the uniformity and smoothness of the elevator’s counterweight and cabin movement.

Unlike other guide shoes on the market that use a spring for damping, General Cabin’s design guide shoes benefit from a plastic intermediary.

One of the advantages of using rubber is the ability to react quickly and effectively to applied forces and reduce the vibrations of the cabin assembly and its accessories.

The method of attaching and installing this rubber to the body of the guide shoe is such that it allows the moving part of the guide shoe the possibility and ability to move in various directions: vertical, horizontal, and angular.

The use of bent sheet metal in the body of the guide shoe increases the sheet’s strength and provides suitable resistance against applied forces.

The reinforcement placed behind the guide shoe body increases the structure’s resistance to bending forces. Teflon, a material known for its anti-wear properties, is used for the part in contact with the rail in the Hitachi design guide shoe.

A vertical groove in the rail holder ensures that a certain amount of lubricant is always kept in place, leading to reduced friction between the guide shoe and the rail and, consequently, smoother movement.

A unique design feature is the inclusion of a curved section at the top and bottom of the guide shoe, which allows for gradual contact with the rail. This results in smoothness at the initial start and prevents vibration.

General Cabin’s design guide shoe is capable of being used at speeds of up to 2 meters per second with provisions made for such operation. This guide shoe can withstand pressure with a nominal load of more than 1 kilonewton and has the same capacity to endure lateral forces.

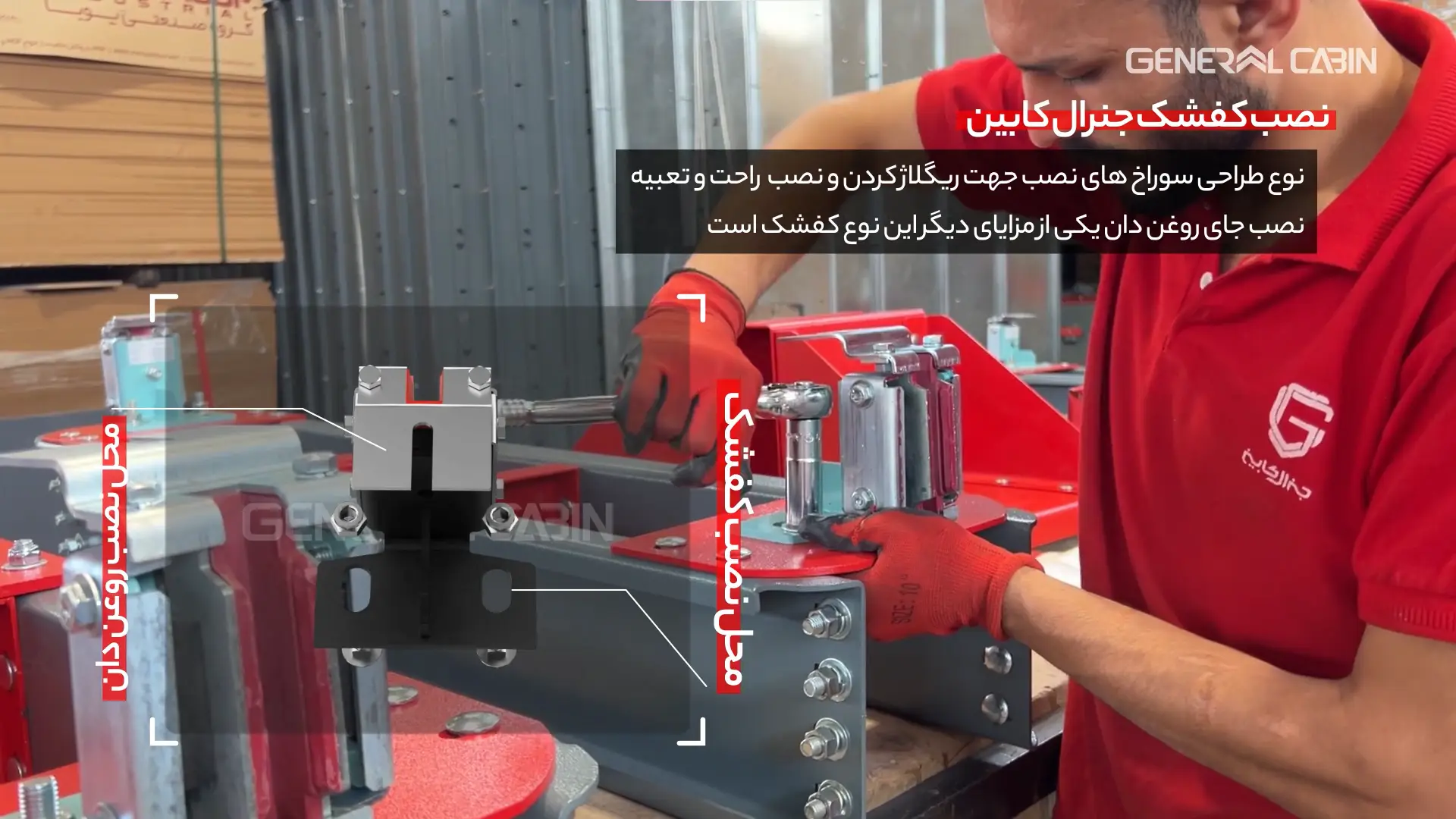

The design of the mounting holes for easy adjustment and installation and the provision for an oil reservoir are other advantages of this type of guide shoe.

Unlike conventional guide shoes that are fastened with four screws, this guide shoe has a large contact surface with the rail, which is significant. This increases the robustness of the guide shoe in heavy-duty applications and larger cabins.