6-Person Capacity Elevator Cabin

The 6-person elevator cabin is one of the most common elevator cabins for residential buildings. This elevator cabin is also used for office buildings with relatively low density.

Suitable decorations for the 6-person elevator

Dimensions of the elevator cabin for 6 people

To construct an elevator cabin, we require precise information, one key element being the dimensions of the elevator shaft. Measuring the elevator shaft allows us to maximize the compatibility between the cabin and the shaft. Otherwise, the constructed elevator cabin might not be executable and could lead to numerous issues.

The necessary measurable components vary between different types of elevators, such as hydraulic and traction. Still, the main ones common across all elevators are the width, depth, and threshold of the elevator cabin door, which are used to calculate capacity.

The cabin width corresponds to the wall facing the cabin and the depth, to the side wall of the cabin. To determine the cabin’s capacity, we multiply the cabin’s width by its depth and add it to the area of the door threshold (threshold length by threshold depth).

The resulting figure is placed in a table of cabin dimensions and capacity to analyze the number of people the cabin can transport.

According to national building regulations, the dimensions of a six-person elevator cabin, which has a carrying capacity of 450 kilograms, range from 1.17 to 1.30, and the dimensions are 112 by 112 with a minimum height of 220 centimeters. These dimensions can proportionally vary.

If you lack the expertise to take measurements and perform calculations, General Cabin’s measurement and engineering team offers free shaft measurements and provides the drawings.

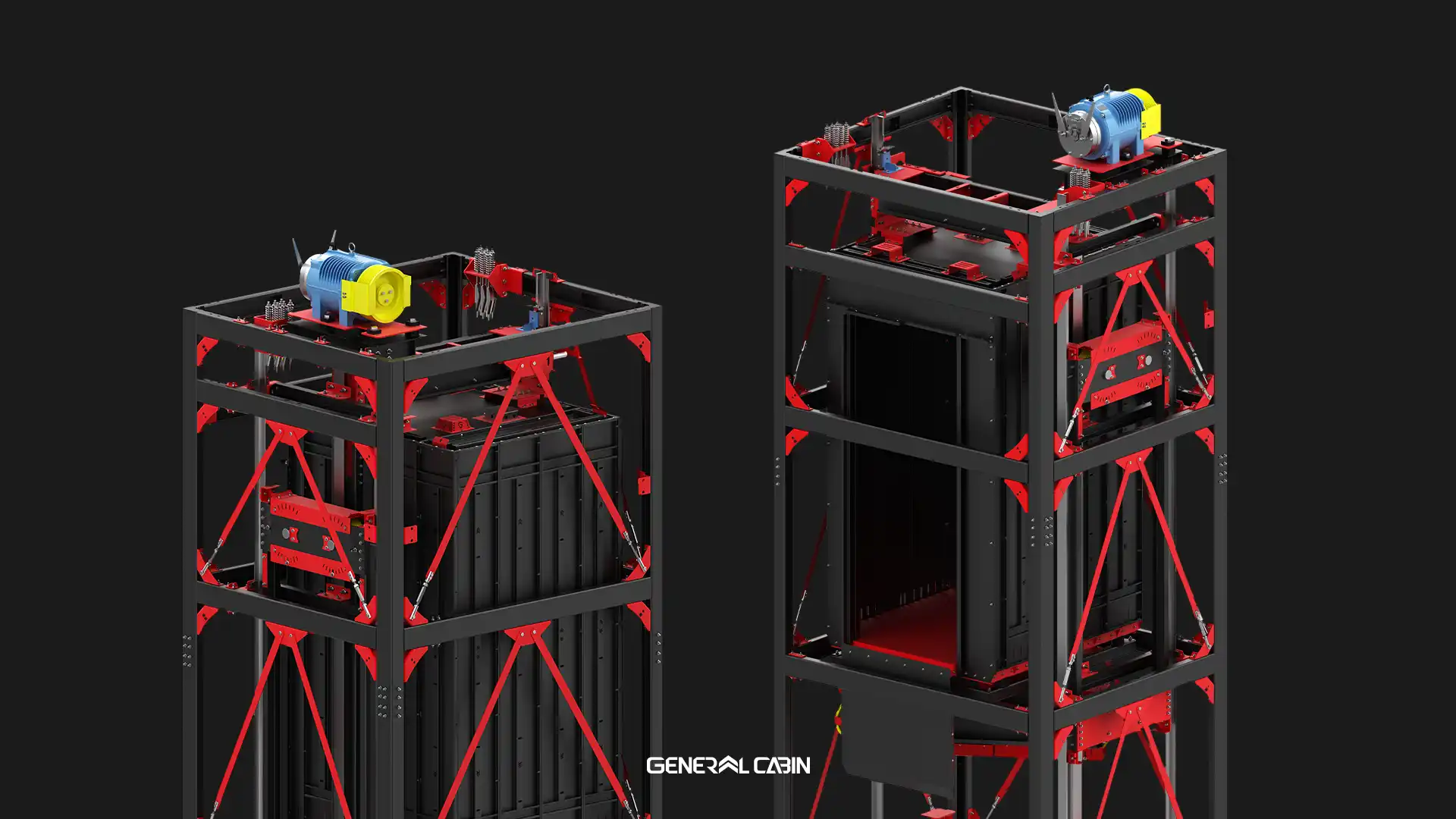

What type of motor for a six-person elevator?

The motor is one of the most important components of any elevator, being the driving force of the system, and selecting the most suitable motor is always paramount.

Factors to consider when choosing a motor include speed and capacity. In fact, before purchasing any type of elevator motor, you should check its usability and efficiency, then proceed.

Generally, elevator motors fall into categories such as gearless, geared, and magnetic, with gearless and geared motors being the most utilized in Iran.

The most prominent and high-quality geared motors include Sassi, Sicor, and Montanari motors, all of which are made in Italy and considered some of the best motors in the world.

If your elevator uses a gearless system, our recommendation would be Ziehl-Abegg and Wittur motors from Germany.

What is the approximate weight of a six-person elevator?

The overall weight of an elevator cabin is derived from the sum of its components’ weight plus the weight of the maximum number of passengers it can carry.

Elevator cabin weight = Weight of the elevator cabin without decorations + Cabin decorations + Flooring stone + Counterweight of the cabin + Elevator door + Weight of passengers inside the cabin

The approximate weight of each person is about 75 kilograms, which for a six-person elevator cabin amounts to 450 kilograms.

The weight of the six-person elevator cabin without decorations is 220 kilograms, and with decorations, it reaches 510 kilograms.

The weight of the flooring stone depends on whether it is natural or artificial, with natural stones generally weighing more than artificial stones, about 75 kilograms.

The counterweight of the elevator cabin is approximately 260 kilograms, and the weight of the door is about 90 kilograms.

Price of a six-person elevator cabin

One of the factors that influence the price of a six-person elevator cabin is the type of elevator, whether it is traction or hydraulic. Another factor is the capacity and height of the cabin, with increases in these aspects directly correlating with an increase in cabin price.

Decorations also affect the price. Some specific decorations that undergo different processes and use different materials can be more costly, for example, the Zaha elevator cabin which is produced using molds and primarily utilizes glass as the decorative material, or the Victoria elevator cabin which is designed with the use of MDF.

For more detailed information and precise price inquiries for your project, you can contact the sales team experts and receive free advice.

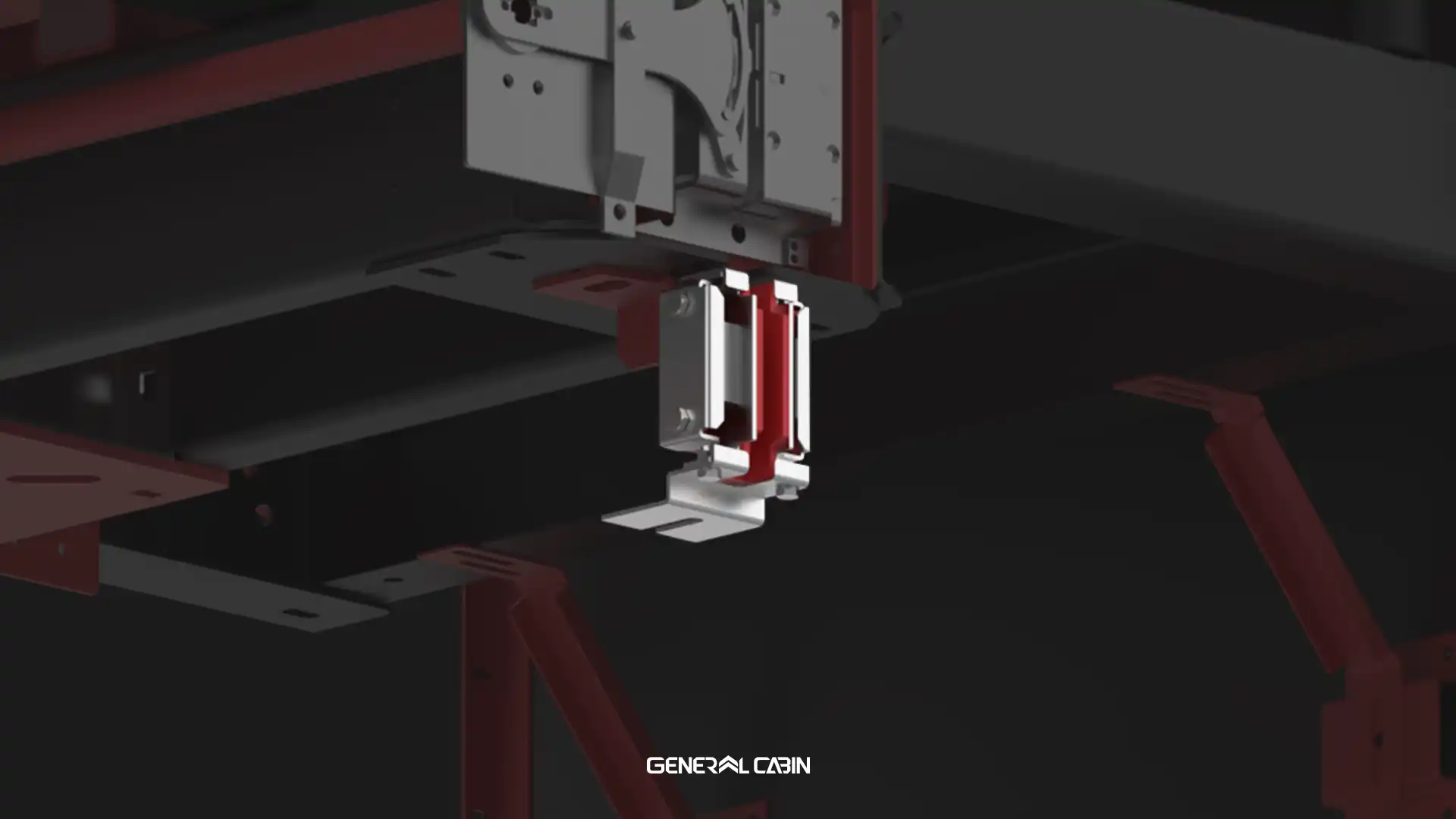

Suitable rails for a six-person elevator cabin

The metallic components with a T-shaped cross-section in elevator construction, used for guiding the cabin or counterweight, are the cabin rails or counterweight rails.

The rails have important functions such as guiding the counterweight and cabin in vertical motion, minimizing horizontal movement, resisting cabin fluctuations due to centrifugal forces, and stopping the cabin when the safety mechanism is activated.

The cabin and the counterweight frame are connected to the elevator rail via a shoe. These rails are automatically lubricated on both sides along the movement path. Clips and brackets securely attach the elevator rails to the elevator shaft’s structure.

Generally, for a six-person elevator cabin, T70-size cabin rails and T50-size counterweight rails are used. Due to the capacity not being very large and the cabin’s relative size not being particularly big, there is not necessarily a need for larger rails. However, some prefer to use T90-size cabin rails and T50-size counterweight rails.

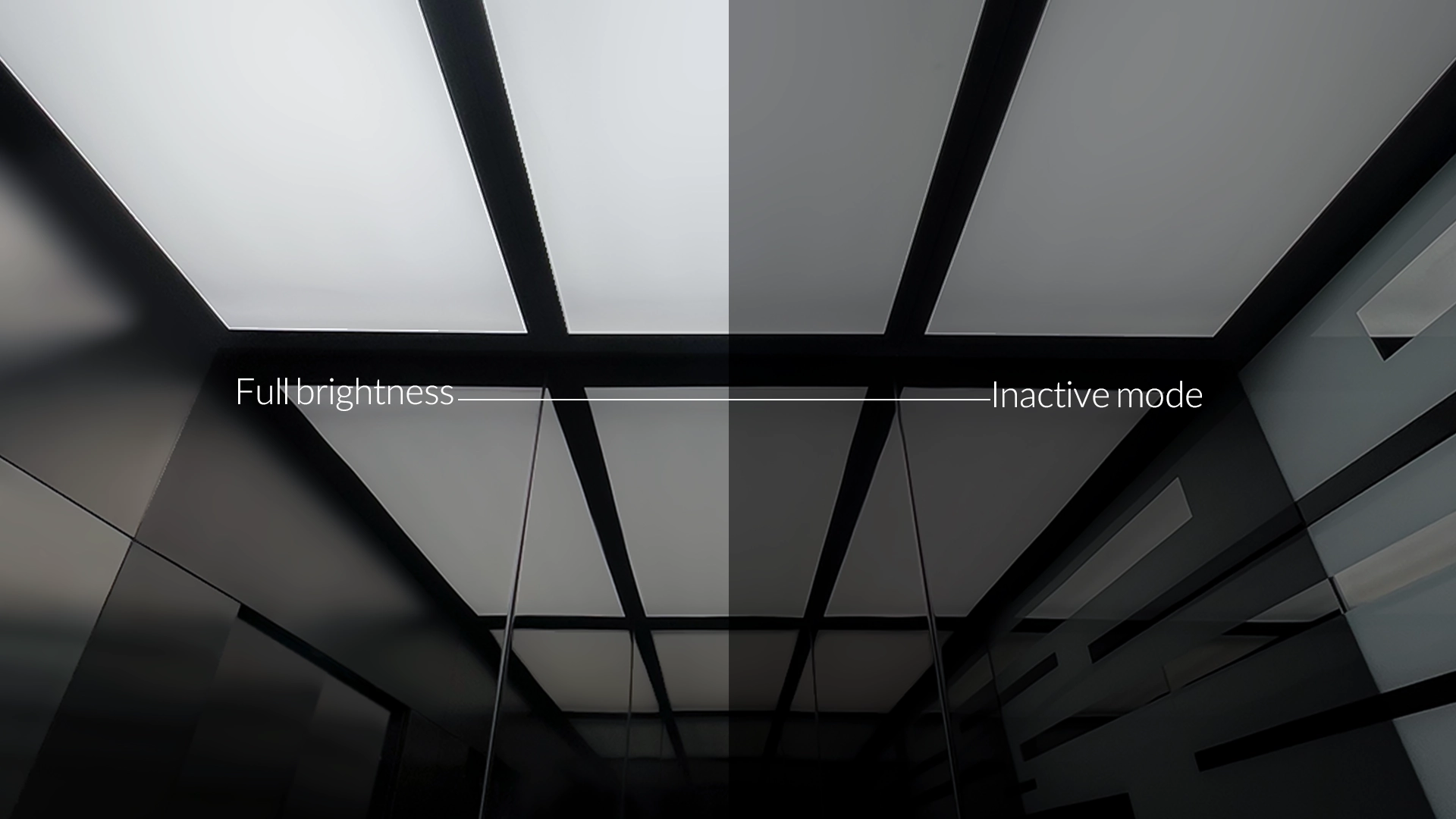

Cabin illumination

The lighting inside an elevator cabin is one of the most influential elements in terms of aesthetics and creating a positive feeling for the passenger. It is also very important for safety and preventing potential hazards.

When lighting inside an elevator cabin, attention must be paid to the ceiling height and its continuous movement. Appropriate methods and tools must be used to achieve proper illumination inside the elevator cabin, by its conditions and dimensions.

To supply light inside the cabin, LED, SMD, and halogen lights are commonly used, which vary depending on the type of decorations and interior design of each cabin. For example, LED lights are mostly used for linear lighting decorations, while halogen lights are used for point-source lighting.

In terms of standards, the permanent lighting within the cabin, which includes the illumination of push buttons and in front of the door, should be at least 50 lux. However, when the cabin is active, meaning passengers have entered and the cabin is in motion, the interior space of the elevator cabin should be fully lit, ranging from 150 to 200 lux, which also contributes to a better appearance of the elevator cabin.