What is an elevator bracket?

An elevator bracket is one of the essential parts that act as a restrainer for the guide rails of the cabin, serving as a connector between the elevator rails and the ironwork or structure within the elevator shaft.

Elevator rails are a crucial component of the elevator system that, if installed correctly, allow the elevator to move up and down smoothly and without any issues. Proper rail installation ensures no vibrations during the elevator’s operation, allowing the elevator to function at its best.

An elevator bracket acts as a corrector and adjuster for any deviations from the plumb that may occur in the elevator shaft. If the elevator bracket is functioning correctly and is properly positioned, the elevator can also move up and down correctly.

The use of elevator brackets

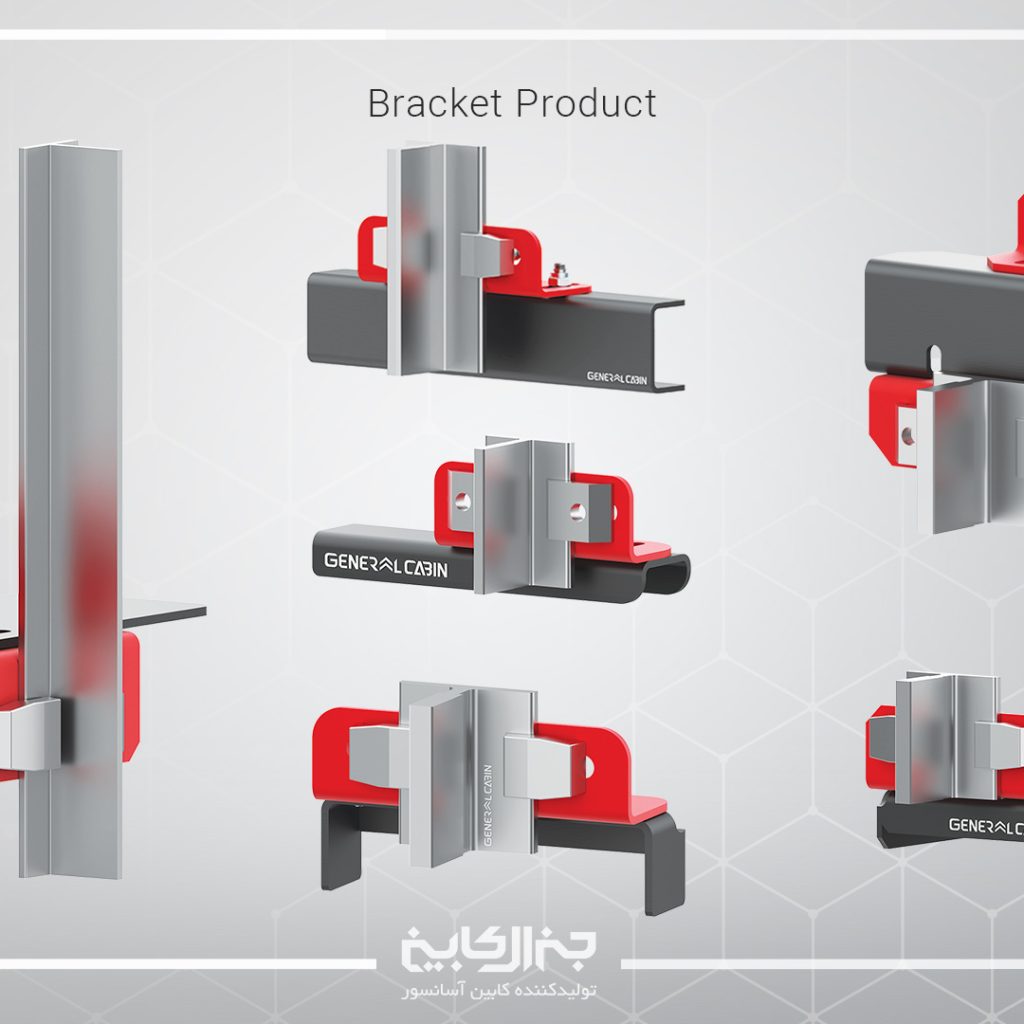

We must say that brackets are bases where the elevator rails are mounted to the structure or the walls of the shaft, and they play a fundamental role in the correct installation and positioning of the elevator rails.

The size and type of elevator bracket are selected based on factors such as movement speed, size and type of rail, safety brakes, and elevator cabin capacity.

As mentioned in the beginning, the correct and proper installation of elevator rails depends on the quality and accurate execution of the brackets. This means that if the elevator brackets function properly even in their most minor aspects, you will have a high-quality elevator without issues.

However, the installation of this component must be done with precision and detailed craftsmanship to show adequate performance based on the expected function. The point of installation and connection of this component is to a structure, a brick or concrete wall, or a metal beam.

This part is constructed simultaneously with the building and might not exist in some buildings, which would then require installation after the necessary coordination.

In Iran, an ironwork method is used. With this method, the dimensions and types of beams and the distances between them need to be examined according to the building’s blueprint. Usually, in the ironwork method, brackets are connected to the building’s steel frame, which vastly influences the better installation of the elevator.

Bracket Construction Material

Usually, iron sheet corners and studs are used to make this piece, and this material can be used to make elevator brackets.

At General Cabin, the brackets are made from Mobarakeh steel sheets with thicknesses ranging from 8 to 20 millimeters, depending on the capacity and type of the elevator, and are coated with electrostatic oven paint, which is entirely rust and scratch-resistant.

Elevator Bracket Installation Location

The elevator bracket is attached to structures or walls. The safer and more secure the installation site of this component, the better will be the quality and efficiency of the rails.

These two parts of the elevator (bracket and elevator rails) have a direct impact on each other, and the brackets must be correctly placed in the building for each rail. Proper distance from the doors on each floor and about the other brackets along the shaft is essential. This adjustment of distance and spacing is carried out by specialists and various elevator manufacturing companies and is a very precise and important task.

Base Brackets

At the bottom of the shaft, where the installation of the rails begins and is anchored, different types of base brackets or special base plates for rails are used. These brackets are attached to the bottom of the shaft using bolts and nuts.

Elevator Clamp and Bracket

The clamp, also known as the elevator clip, is a part that is used in various sections of the elevator, including the bracket, and its function is to hold the retaining objects firmly and securely in place. For example, a bracket clamp is used to connect the rail to the bracket, and each bracket is connected to the rail with two rail clamps.

To calculate the number of clamps in an elevator, we first need to calculate the number of brackets. To do this, we multiply the number of rails used by three. Therefore, for each rail section, three brackets are used. Now, if we double the number of brackets, we get the number of clamps.

Clamps generally fall into two categories, cast and pressed, and they are cast iron or steel.

Functions of the Elevator Bracket

Now that you are familiar with this elevator component, we should say that elevator brackets are parts that are firmly attached to the structure. For this reason, this component cannot be adjusted at the installation site, and therefore, it needs to be handled with great precision before installation.

While the rails can be adjusted using filler sheets, adjusting the brackets after installation is not possible.

To install elevator brackets, angles or rolled metal sheets with slotted oblique holes are used.

The distance between the brackets in an elevator is at least 1.5 meters and at most 2.5 meters. These dimensions can vary according to the elevator rails.

Bracket Price

At General Cabin, brackets are not sold separately and are provided with each project upon request.

For free consultation and price inquiries, please contact the sales department.