Elevator

An elevator facilitates the rapid and easy movement of people and goods from floor to floor in buildings and is considered one of the symbols of advanced and valuable technology in the modern age.

Today, elevators are indispensable in importance and vitality, from residential to commercial, office buildings, and even tall and complex structures such as towers. They not only contribute to improving daily life’s comfort and efficiency but also facilitate the enhancement of safety and the development of urban spaces.

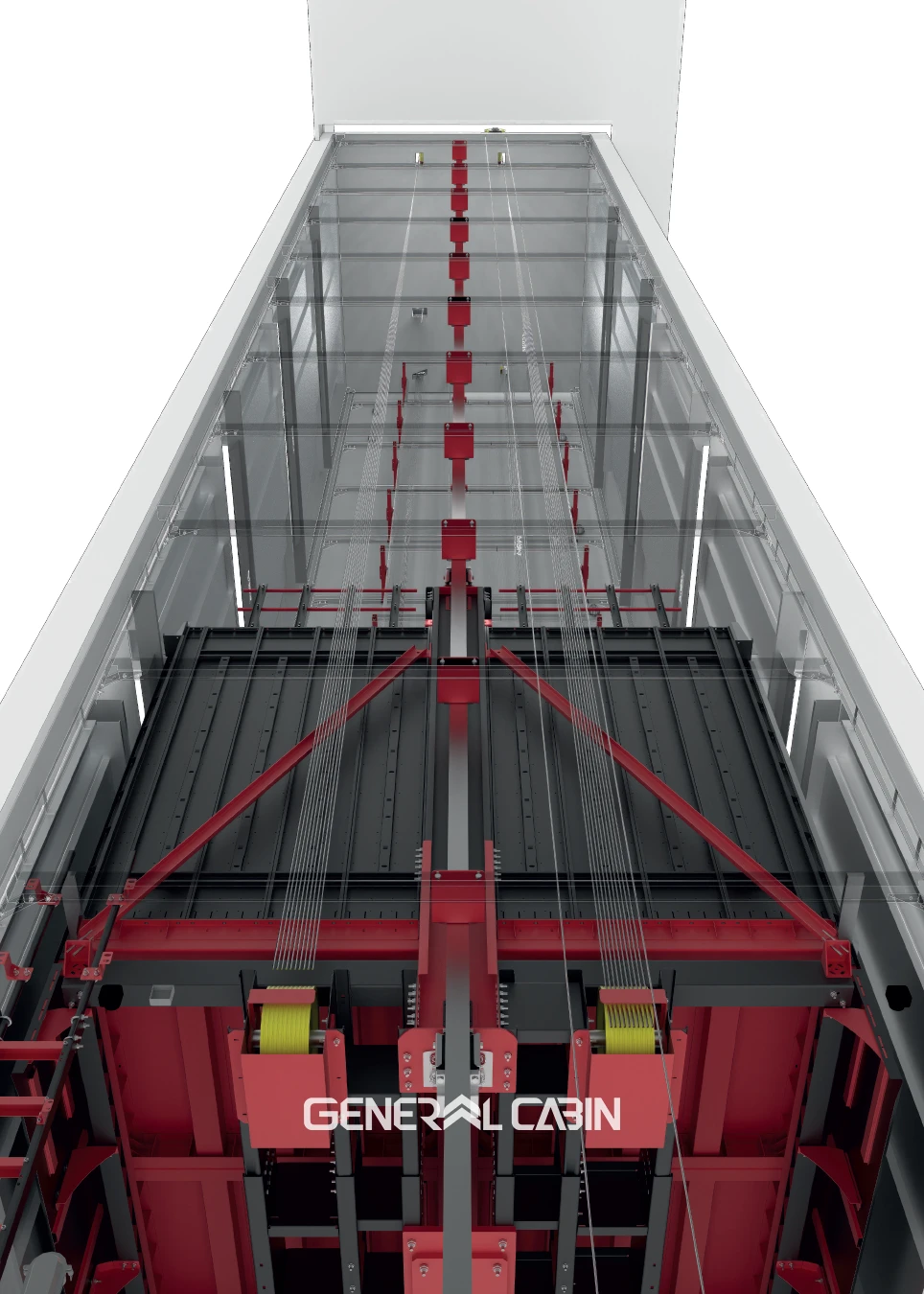

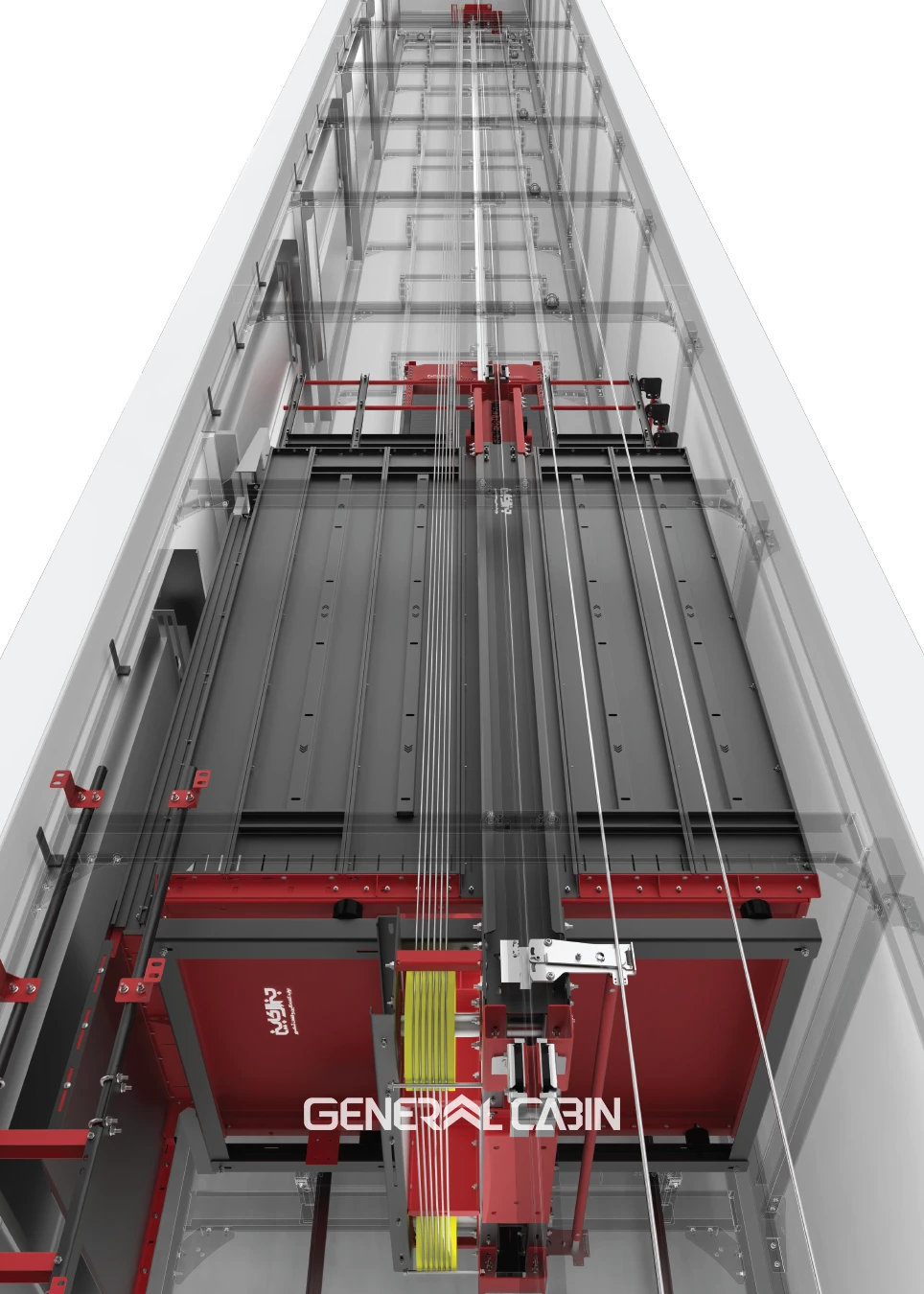

Components of an Elevator

Elevators, as fundamental transportation systems in buildings, can move people and loads from one floor to another through a complex combination of mechanisms, electronics, and intelligent controls.

1. Elevator Motor: The elevator motor, as its heart, is responsible for generating mechanical force to move the elevator cabin up and down. Typically, these motors are electrically powered, using electrical energy for motion.

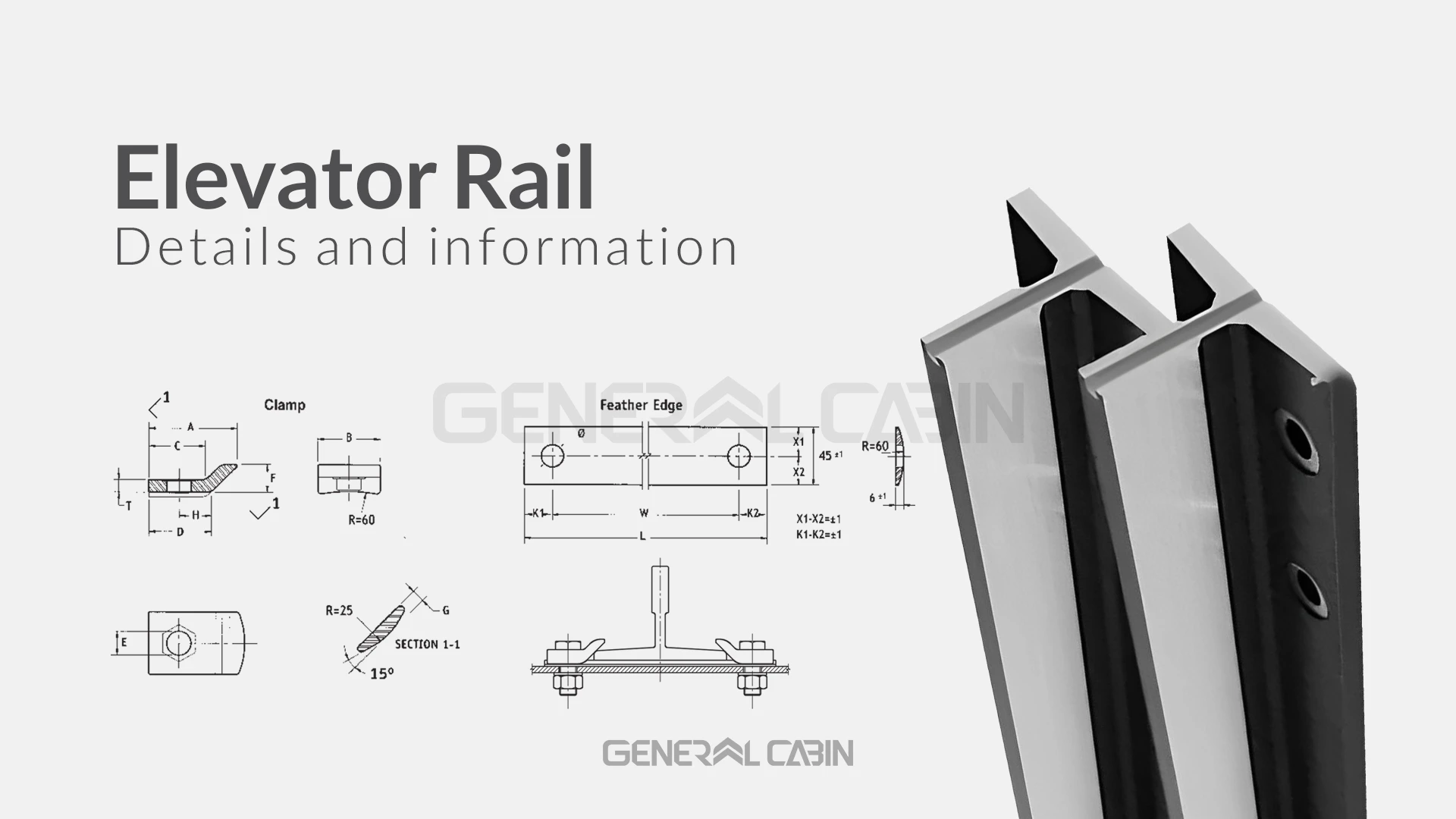

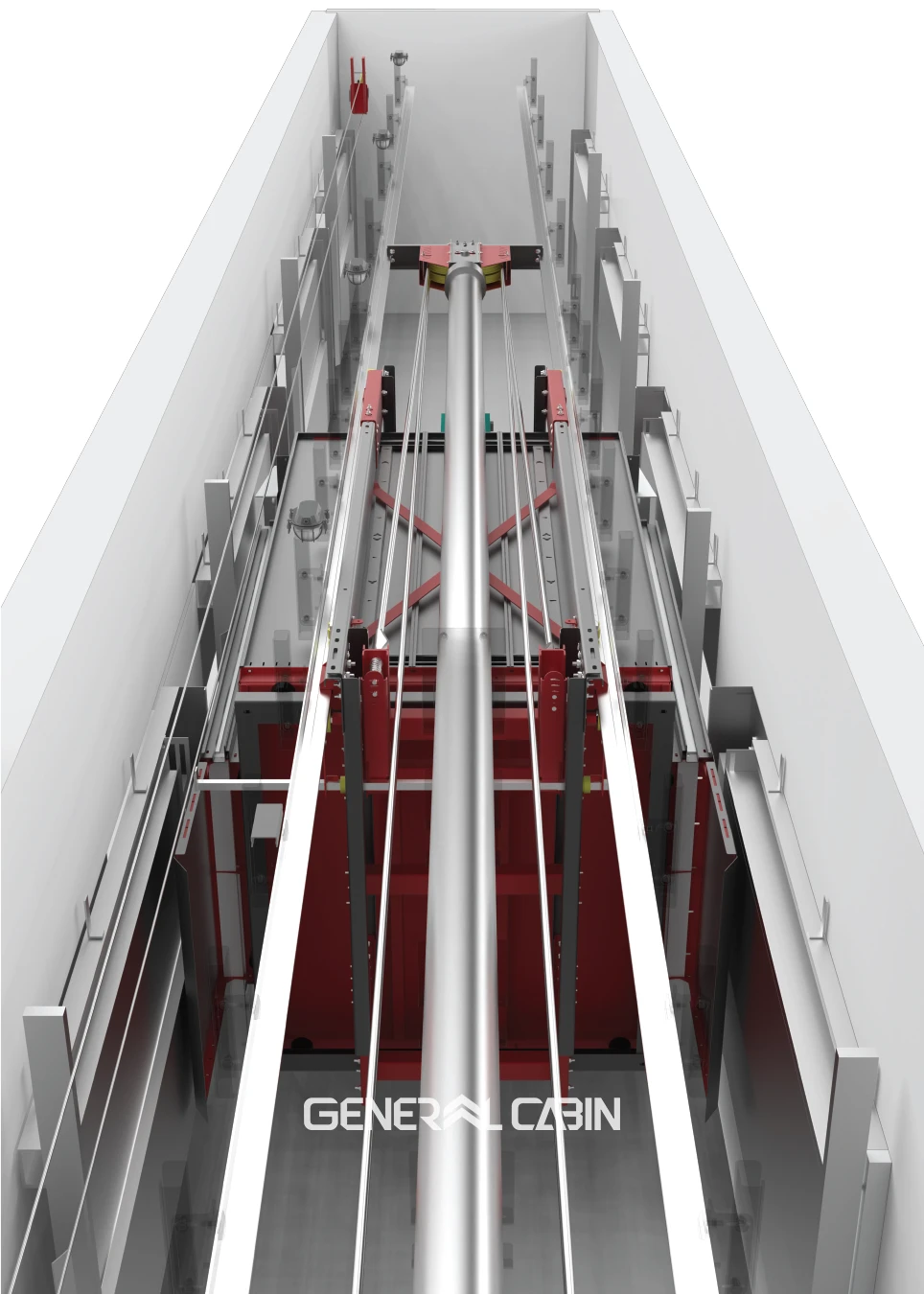

2. Elevator Rail: The track or rail is a structure upon which the elevator cabin moves. Installing rails inside the elevator shaft ensures smooth and safe movement of the cabin.

3. Elevator Cabin: The elevator cabin, a vital and intricate part of the elevator system, must comply with a set of safety standards and regulations in addition to transporting people and loads between different building floors. This space is designed and constructed considering factors such as structural integrity, intelligent systems, ease of use, ergonomic design, and emergency facilities.

Design engineers consider various aspects in the design of elevator cabins such as air ventilation, lighting, sound, and safety equipment. Typically, cabins are made of metal or glass to be suitable in terms of strength and aesthetics for the elevator environment.

Cabins are equipped with handles, control buttons, and displays that allow users to control movement and select desired floors. Modern technologies and innovative control and communication methods are utilized in designing this part of the elevator to improve the travel experience for users.

Elevator cabins are equipped with safety systems such as motion sensors, smoke and fire detection systems, status monitoring systems, and emergency systems that safely guide passengers and loads in the elevator in case of problems. These additional features improve the performance of elevator cabins and ensure that emergency measures can be quickly and fully implemented in case of incidents.

- Elevator Safety System: Gates control entry and exit from the cabin and safety systems such as sensors and control systems ensure passengers’ safety during elevator movement.

- Elevator Control Panel: This system is responsible for managing elevator movement. Among its tasks are planning movements, speed control, and providing information to users about the elevator’s status.

The elevator control panel serves as the central management and control center for the elevator, as its name suggests. All commands given by users are initially sent to this panel, and after processing, the elevator executes them. Elevator control panels must be capable of providing an emergency rescue system in case of power failure and must be protected from damage to electronic components when exposed to dust. Additionally, they should have suitable ventilation systems to prevent temperature rise. These control panels are manufactured in two types: variable speed and 3VF, and installation and operation are based on the building’s characteristics.

6. Cabin and Floor Doors: Overall, there are two types of doors for elevators. The first type is floor doors, the number of which equals the number of elevator stops in the building. The second type is cabin doors. Typically, cabin doors are installed automatically in various types such as central, telescopic, and bus, provided that the site conditions allow. Additionally, floor doors are produced in two different forms: semi-automatic or manual and fully automatic, in central or telescopic types. The type of elevator door is chosen and installed based on the site conditions.

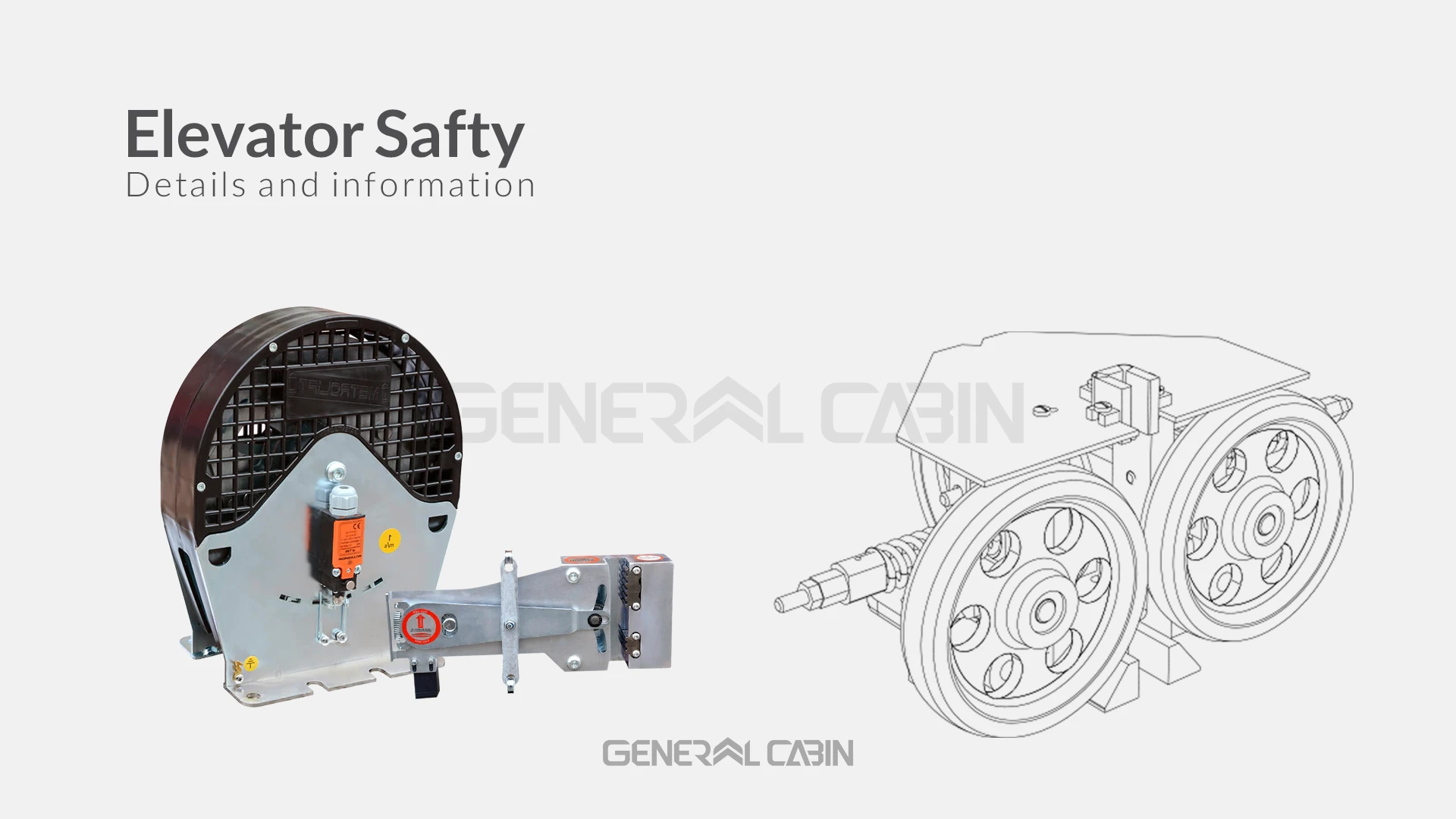

7. Governor and Safety Gear: When the speed of elevator movement exceeds the designated limit, the elevator’s safety brake activates to prevent falling and other accidents. As the elevator cabin’s speed increases, the governor detects this unauthorized speed and activates the safety gear, connected to the cabin by the governor’s cable, which is pulled by the governor’s centrifugal force, preventing the cabin from falling. Elevator brake systems operate in two modes: electrically, by switch disconnection, and mechanically, by the safety gear’s activation. For increased assurance, they are manufactured and installed by elevator standards. Elevators must necessarily have an emergency brake system; otherwise, their use is illegal.

- Buffer: Elevator buffers, made in various types, but most commonly in polyurethane and hydraulic forms, serve to cushion the elevator’s impact. Polyurethane buffers are used in elevators with low capacity and speed, while hydraulic buffers are used in elevators with high capacity and speed. The buffer or shock absorber does not prevent elevator fall; its purpose is to prevent the cabin from descending excessively on the lowest floor.

- Traveling Cable: The traveling cable is the main interface between the elevator cabin and the control panel. Due to its high sensitivity, this equipment must be made of high-quality materials. The traveling cable’s function is to transmit all commands, including floor summoning, cabin lighting, telephone, emergency stop, position indicator display, overweight sensors, switches, and others, between the panel and the cabin. This cable is flat to provide greater flexibility during elevator movement. Typically, these cables consist of 12 or 24 wire strands of size one and are selected and installed based on the system type.

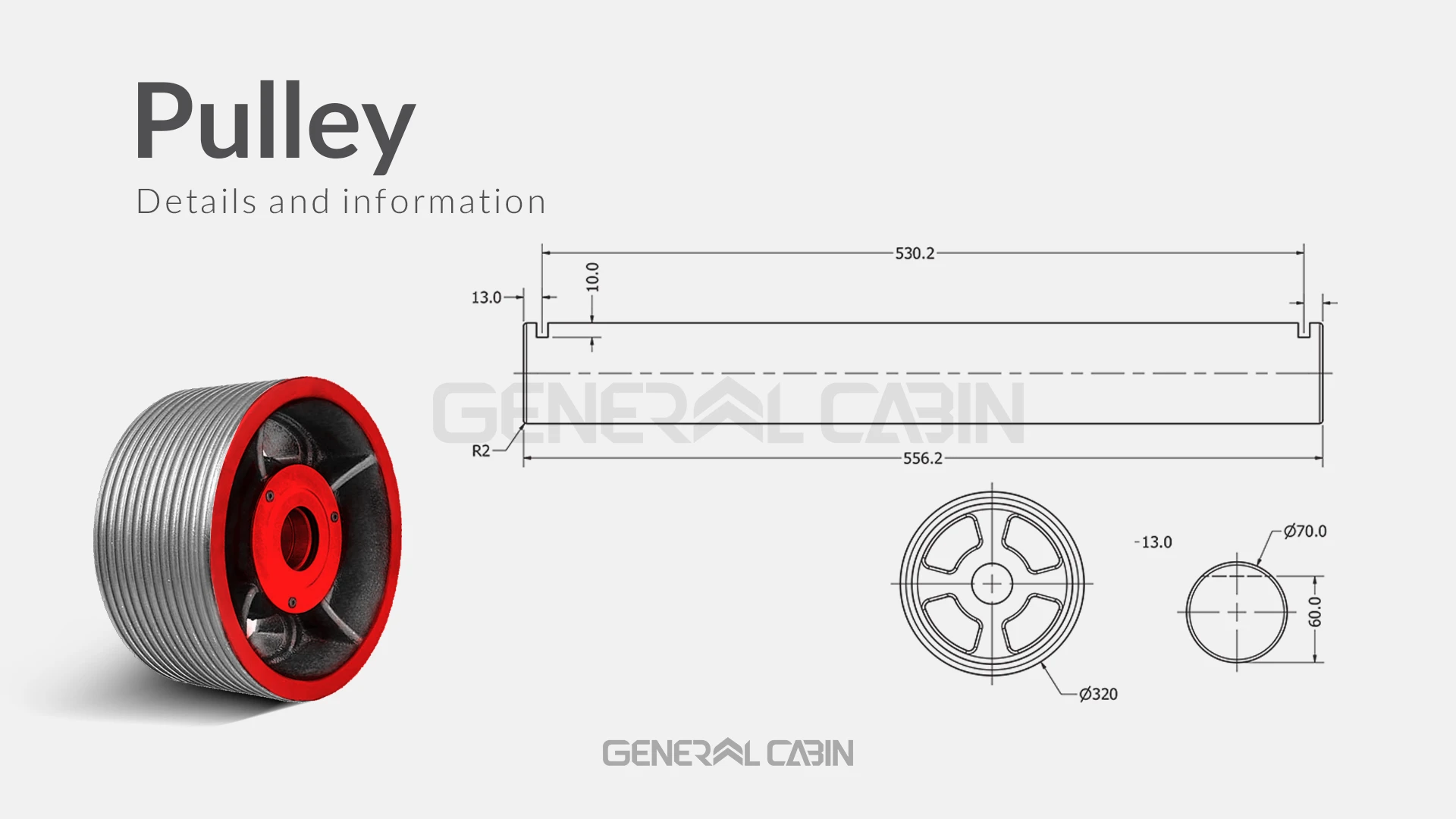

- Deflector Sheaves: Deflector sheaves, also known as diverting pulleys, guide the governor ropes to the desired location. These sheaves are produced in two types: ordinary and roller guides. Roller guide deflectors are mainly produced for gearless elevators, which can withstand heavier loads, while ordinary deflectors are made for geared elevators used only for guiding the governor ropes. These sheaves are made in different sizes and grooves for various types of ropes. Additionally, deflector sheaves are produced in four types U-groove, V-groove, U-groove undercut, and V-groove undercut. Deflector sheaves are part of the elevator suspension system.

11. Governor rope: Governor ropes are used in traction elevators to move and bear loads, and they come in various types used in different industries. These ropes are made of steel fibers and consist of a set of wires, wire layers, and a core twisted together to form a steel cable. Steel wires, or “strands,” form by twisting around themselves, and these strands, by twisting around a “core” or cable center, form the steel rope or cable. Ropes come in various sizes, with common sizes in the elevator industry being 6, 8, 10, and 12 millimeters. Additionally, steel rope cores come in various types, with the most common types in the elevator industry being steel cores and fiber cores.

Types of Elevators

When considering the types and speeds of elevators, we can categorize these devices into several main groups:

- Hydraulic Elevators:

These elevators use a hydraulic cylinder to move the cabin. The hydraulic fluid is typically oil or water. Due to the need for less space for moving mechanisms, they are suitable for buildings with limited space. Their smooth and gentle operation, high safety, and minimal maintenance requirements are among their advantages.

- Traction Elevators:

The cabin is pulled by a cable or rope in these elevators and held on a guide rail. This type of elevator is mainly used in tall buildings with heavy loads but requires significant space. The ability to move at high speeds, precise control, and the capability to transport heavy loads are features of these elevators.

- Winch Elevators:

The cabin moves up and down using a winch and cable in this type of elevator. Due to the use of a simpler mechanism, it allows for speed adjustment and more precise movement. They are primarily used in towers and very tall buildings and are suitable for transporting people and light loads.

- Pneumatic Elevators:

These elevators use the ambient air pressure to move the cabin. Due to their simple structure and lack of multiple mechanical parts, they are quick and easy to install and operate. They are mainly used in small buildings and serve as urban or station elevators.

- Magnetic Elevators:

In these elevators, the cabin moves using magnetic force between magnets placed in the cabin and magnetic rails. They are mainly used for vertical movement in small buildings with low traffic and are typically used as urban elevators or in stations.

- Hybrid Elevators:

These elevators use a combination of two or more different technologies for cabin movement. This combination of technologies can improve elevator performance, efficiency, and safety, making them suitable for buildings with special requirements.

- Panoramic Elevators:

These elevators have glass walls that allow users to experience a beautiful view of the surrounding area. They are mainly used in tourist buildings, hotels, and shopping centers, providing a delightful traveling experience.

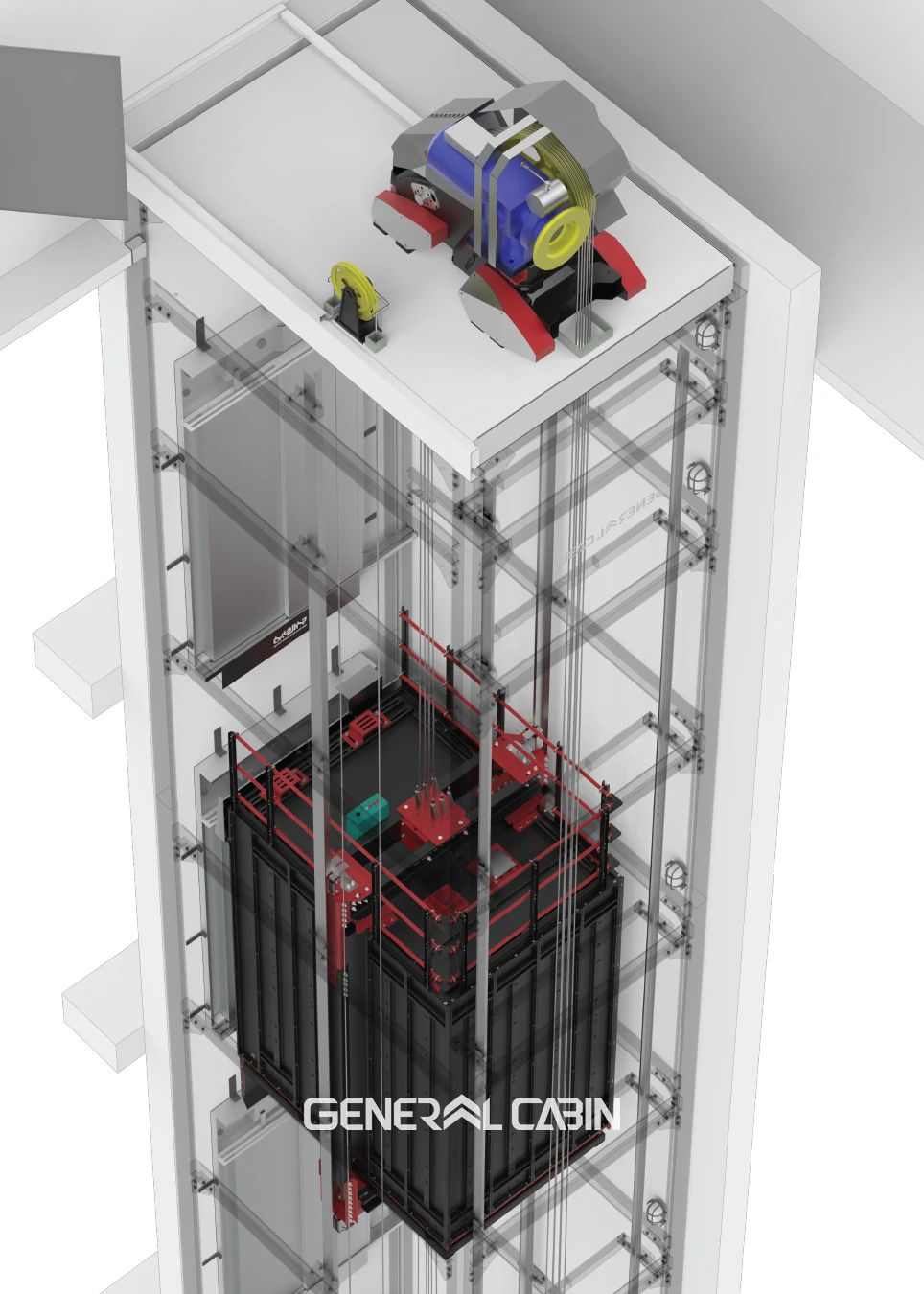

- MRL Elevators:

Machine Room-Less (MRL) elevators are a type of elevator that operates without the need for a separate machine room, unlike traditional elevators. In these elevators, all motor components and moving mechanisms are placed in a small space inside the elevator shaft.

The motors used in machine room-less elevators must be gearless because they have much less volume compared to geared motors. In gearless systems, whether operated with or without a machine room, since the suspension system is in a two-to-one configuration, the motor rotation speed will be twice the speed of cabin movement. This means that if a lift with a speed of 1 meter per second is required, the motor must rotate at a speed of 2 meters per second.

Additionally, in machine room-less elevators, the suspension system is designed in a two-to-one configuration. In this system, the fixing of the sheave boxes, instead of being placed on the cabin and counterweight, is fixed at the highest part of the elevator shaft. After fixing one side of the sheave boxes and passing through the sheave bushings and the counterweight, the motor bushings and then the cabin bushings are re-closed at the base of the motor pulley.

- Smaller Space: Since there is no need to build a machine room in these buildings, the usable space in the building increases.

- Cost Savings: By reducing the need for building and installing a machine room, the costs of building and installing MRL elevators are reduced compared to MR elevators.

- Maintaining a Beautiful Appearance: Since MRL elevators do not require a machine room, they maintain the appearance of the building, which may be affected by the extra volume of the machine room.

- Easy Maintenance: All mechanical components are located inside the elevator shaft, making access to parts easier for repair and maintenance.

- MR Elevators:

MR (Machine Room) elevators are another type of elevator where a separate and dedicated machine room is installed for the motor and elevator control systems. In this type of elevator, the machinery and equipment are usually located in a separate space on the same level or lower levels of the building.

- Higher Efficiency: Some MR elevators use larger motors and more advanced control systems, which improve elevator performance. MR elevators have much higher capacity compared to MRL elevators. This makes MR elevators the only option for capacities exceeding 1150 kilograms.

- Noise and Vibration Reduction: One of the main advantages of MR elevators is the reduction in noise and vibration during operation, which positively affects the quality and comfort of the ride. This advantage is particularly noticeable at higher speeds. For this reason, MR elevators are a suitable option for speeds equal to or greater than 1.75 meters per second. However, during operation, machine room-less elevators have more noise and vibration, which may be unpleasant for some users.

- Patient Bed Elevators:

Patient bed elevators are installed in hospitals for patients who are unable to sit in a wheelchair. These elevators have features such as having doors on both sides of the cabin and a very smooth and gentle movement system. Due to the large volume and dimensions of the cabin, these elevators must have high capacity and power to easily transport patient beds and medical equipment when necessary.

Patient bed elevators must meet the following requirements:

- The minimum dimensions of the cabin must be 1400 by 2400 millimeters.

- The minimum width of the cabin door opening must be 1300 millimeters, and its height must be 2100 millimeters.

- It must be equipped with a 3VF system, cabin door hold-open button, emergency rescue system, floor re-leveling system, and a special key that grants access to trained and authorized individuals.

- Patient Lift Elevators:

Patient lift elevators, installed in healthcare centers and hospitals, are designed to transport patients who cannot be moved from their stretchers between floors. These elevators must have high capacity and weight-bearing capabilities to ensure no issues arise when a patient, along with medical staff and companions, are in the elevator cabin.

Patient lift elevators must meet the following requirements:

- The minimum dimensions of the cabin must be 1100 by 2100 millimeters.

- The minimum width of the cabin door opening must be 900 millimeters, and its height must be 2000 millimeters.

- They must be equipped with a 3VF system, cabin door hold-open button, emergency rescue system, floor re-leveling system, and a special key that grants access to trained and authorized individuals.

- Wheelchair Lift Elevators:

Wheelchair lift elevators, also known as wheelchair-accessible elevators, can transport a wheelchair or mobility device. Due to their smaller dimensions, these elevators are among the most common types.

Wheelchair lift elevators must meet the following requirements:

- The minimum dimensions of the cabin must be 1100 by 1400 millimeters.

- The minimum width of the cabin door opening must be 800 millimeters, and its height must be 1800 millimeters.

- They must be equipped with a 3VF system, cabin door hold-open button, emergency rescue system, floor re-leveling system, and a special key.

- Car Lift Elevators:

In today’s world, with a large volume of cars present in every city, parking issues gradually become a global concern. For this reason, property owners and building contractors seek to use multi-level parking lots and car lift elevators to address these challenges. Car lift elevators, based on site conditions and load capacity, are installed in either traction or hydraulic configurations.